How is whisky made?

Making whisky is a complex process that goes through multiple stages. Although the process has been known since ancient times, the subtle aromas and flavors of whisky have not been fully explained until now. Table of Contents What is whiskey? Whiskey is an amber-colored distilled liquor made from fermented grains (usually rye, wheat, corn, or

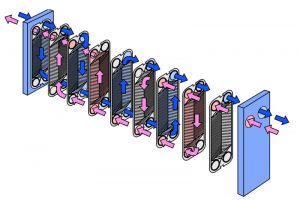

What Are The Different Types Of Heat Exchangers?

Various industrial processes rely on heat exchangers, to aid in transferring heat between different media that efficiently. There are many kinds of them, each designed for specific uses and applications. Knowing the different types of such equipment can help you choose one that is best suited to your particular needs.

What Are The Common Types Of Beer Brewhouse Equipment?

Before we break down the details of brewhouse equipment, let’s take a minute and look at what it means. By this I mean that brewhouse equipment comprises all machinery and vessels utilized in brewing beer. These include mash tuns, brew kettles, fermenters etcetera. It is from these components that we get wort which through fermentation

50L home brewing equipment shipped to France

The 50L home brewing equipment is made of food-grade stainless steel. Through the built-in intelligent temperature control system, it can accurately control the fermentation temperature and provide the best growth and activity environment for yeast. It is suitable for home use, small bars, restaurants and other commercial places. Micet is a leading beer equipment manufacturer in

What is the right housing material for your beer equipment?

In the beer brewing industry, the material of your equipment’s housing is critical to ensuring the quality of your beer, maintaining the hygiene of your equipment, and increasing your productivity. When you visit a brewery you will find different beer equipment housings, generally in two main categories: stainless steel and copper. Stainless steel can be

Compact brewing equipment best suited for microbreweries

Compact brewery equipment is designed to minimize space usage while ensuring efficient production capacity and quality control. Compact brewery equipment systems can perfectly meet the needs of craft brewers. The key is to combine flexible brewing processes and brewing scales with the usually very limited available space. Diversified brewing on a limited basis promotes the

A Guide to Beer Brewing Trends for 2024

Although the beer market saw some decline in the last nine months of 2023, experts consider it one of the most stable markets, capable of creating trends and successfully retaining customers. From this article, you’ll learn what to expect in 2024 and what to expect from the beer industry. As the brewing industry continues to

Difference Between Bottled and Canned Beer

The brewing industry continues to evolve, and bottling and canning have become a constant debate between consumers and producers. Each packaging method has its unique advantages and attractions, and making the right choice is not only a matter of personal taste preference, but also a matter of product quality, market acceptance, and environmental impact. This

What’s a nanobrewery?

A nano brewery is a small brewery that produces beer in batches of less than three barrels (93 gallons) at a time. The name nanobrewery suggests a smaller operation than microbreweries, which can grow up to 15,000 barrels of beer per year. Small breweries are usually run by avid home brewers who have turned a

What is beer filtration?

Beer filtration is an important step in the beer production process designed to remove solid particles and suspended matter from the beer to improve its appearance and taste and to extend its shelf life. In all cases, filtration is the key to improving the quality and taste of beer. Whether an individual is homebrewing beer,

Learn more about winemaking

If you want to learn more about winemaking, you can subscribe to our blog for updates. We will update the blog every week so that you can learn more about winemaking.