Why is temperature control important in brewing?

Chilling is an integral part of the brewing process. The quality and integrity of the finished product depend on precise temperature control and reduction at critical stages of the brewing operation.

Can a nano brewery make money?

As the popularity and demand for beer have grown, so has an interest in breweries. Starting a brewery can be an exciting venture for beer lovers, but it can also be a risky and expensive one.

What are the types of fermentation tanks?

To sum up, the conical fermenter is an important part of the beer production process. Its unique design allows for easy yeast harvesting, and efficient removal of carbon dioxide, ensures continuous contact between yeast and wort, promotes fast and complete fermentation and is easy to clean and sanitize. Conical fermenters are a common design used

South African brewing equipment feedback sharing

400 small brewing equipment have arrived in South Africa, and customers have sent feedback photos. He was very satisfied with MICET CRAFT workmanship and service, and praised us a lot. MICET CRAFT has always adhered to the spirit of craftsmanship to create exquisite products. Previous Next The following is the configuration of 400L brewing equipment:

Why is the beer fermenter designed as a cone?

Fermentation tanks are an important part of the beer production process, and their design is critical to ensuring successful fermentation. Conical fermenters, also known as conical fermenters, are a popular design used by many breweries for various reasons. Table Of Contents Advantages of conical fermenter The conical is an “uni-tank”, which means you can do

What are the 3 brewing techniques?

When it comes to brewing beer, there are three main techniques that are used to create a wide variety of different styles and flavors. These three brewing techniques are known as extract brewing, partial mash brewing, and all-grain brewing. Here’s a closer look at each of these techniques. Table Of Contents Extract Brewing Extract brewing

5 Factors to Consider for Brewery Investments

Starting a brewery seems straightforward. Buy some brewing equipment, brew some good beer, and sell it to beverage distributors and local restaurants at a handsome profit. For the thousands of craft brewers that have entered the market over the past 10 years, the reality of running a brewery has proven to be quite different. Craft

List of Best Brewery Equipment to Spend

If you are considering opening a brewery, you may be wondering what small brewing equipment is required for commercial brewing. Like many before you, you’ve discovered that brewing requires a significant capital investment. In this guide, a Micet engineer will go over the basics of what you need and discuss the various options involved.The brewery

2BBL brewing equipment installed in Canada

A Canadian customer purchased a complete 2BBL beer brewing equipment at MICET CRAFT. He was very surprised and kept complimenting us. 2BBL brewing equipment is very suitable for small breweries, restaurants and bars, etc. MICET provides complete brewing system and technical support services. Previous Next Some configurations about 2BBL beer equipment: 500L 2 vessels brewhouse

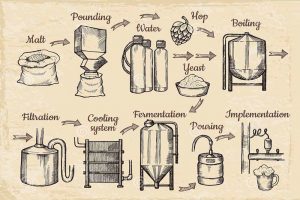

The Seven Steps of Brewing Beer

People always ask, “What does a winemaker do all day?” It’s an easy question to ask. If we watch the team of brewers at work, you see water splashing around, steam spouting from large stainless steel vats, grain being packed into boxes, and a maze of hoses on the ground. But what happened to all

Learn more about winemaking

If you want to learn more about winemaking, you can subscribe to our blog for updates. We will update the blog every week so that you can learn more about winemaking.