The article ‘How To Buy Chinese Brewing Equipment’ is designed to provide all-round guidance for entrepreneurs and brewing fans who are interested in purchasing their brewing equipment from China. The paper takes the reader through the basics of brewing systems as well as international procurement and logistics complexities among others.

Key Takeaways

- Know different types of brewing systems or components available in china, evaluate their quality against your needs (brewing).

- Find trustworthy suppliers; weigh between second-hand versus new machines, also understand import rules plus buying process logistics.

- Customize brewery equipment to meet specific requirements like brewhouse design or automation control system integration.

- Efficiency should be the watchword for any brewery hence this can be achieved by: – optimizing layout & workflow; maintaining machinery; coming up with expansion strategies as well upgrade plans.

- Take advantage of post-sale services such as training offered by suppliers together with consultations and other forms of support. Besides, explore financing alternatives that can bolster your investment in a brewery establishment.

Understanding the Basics of Chinese Brewing Equipment

1、Types of Brewing Systems Available

When you start brewing with Chinese equipment, the most important thing is to know what kinds of systems are available. In the market, there are kits for home brewing on a small scale and commercial systems that are very sophisticated.

A mash tun, lauter tun, kettle tun and whirlpool tun combination usually forms the brewhouse core. These vessels can be arranged in different ways; two vessel, three vessel or four vessel systems among others depending on the complexity of beer produced and also as per brewer’s requirement.

Material choice is also important; stainless steel or red copper being common because they last long and their effect on brewing process.

The flavor of the beer may be influenced by heating method used but this will also affect how efficient brewing process becomes i.e., steam fired vs electric heated etc., so it is necessary to choose appropriate equipment combo matching desired infusion or decoction based on heating approach selected.

2、Key Components of a Brewery Setup

While establishing a brewery, it is important to know what the brewing system involves. These include the brewhouse, fermentation tanks and other auxiliary equipment used in the brewing process. Generally, a brewhouse is made up of a mash tun, lauter tun, kettle tun and whirlpool tun; but these can be arranged differently i.e., as two or three or four vessels depending on the brewer’s preference.

The material used in making these components matters too; stainless steel and red copper are commonly used since they are long-lasting as well as resistant to rusting or reacting with chemicals easily. For efficient cooling of wort, either two-stage or single stage heat exchanger can be employed. Furthermore, a good work platform integration and sanitary wort pump are necessary for cleanliness and operational efficiency respectively.

Lastly, fermentation tanks are where fermentation takes place; therefore their sizes should correspond with batch size & production volume levels. It is important to have standard quality measures for these major items so that one builds a successful brewery.

3、Assessing Quality and Specifications

To ensure Chinese brewing equipment meets the needs of your brewery, evaluate its standards and specifications. One should inquire for a supplier with detailed product testing information such as surface finishes among others like pressure tests or welding inspections. Ensure that quality control is given priority by following global best practices while using internationally recognized parts and electronics.

The most suitable machines are those which not only work efficiently but also have guarantees plus after sale services showing how much faith the manufacturer has in their products.

Below is a checklist to help you ascertain whether the equipment is of high quality or not:

- Surface finish (eg micro polishing 0.2-0.4um)

- Material grade (eg 304/316L)

- Welding quality (eg TIG automatic welding)

- Pressure testing (eg multiple pressure test cycles)

- Certification and compliance with international standards

Moreover, it should be able to give an assurance on delivery time which includes but not limited to delivering equipments on agreed date; providing periodic updates about progress made during production process so far; giving clear project plan showing what will be done at which stage until completion this reflects its commitment towards ensuring customers satisfaction as well success of projects undertaken.

Navigating the Purchase Process

1、Identifying Reliable Suppliers

In order to begin Chinese brewing equipment world, one must first find reliable suppliers. It is important to work with manufacturers who offer good product quality and can be customized for different brewery needs.

Here are some tips on finding reliable suppliers:

- Research & Make A List of Suppliers with Strong Presence in the Industry.

- Check Certifications and Quality Assurance Practices

- Ask About Production Management and Equipment Testing Procedures

- Look for detailed progress updates and informative project scheduling from suppliers

For long term operational success, ensure your supplier has strong after-sales service support.

Don’t forget to ask common questions about product support, shipping, warranties etc. This will help you pick the right partner for a successful brewery setup.

2、Evaluating New vs. Used Equipment

While entering the brewing industry, it is important to decide whether to use new or old brewing equipment. The latest technology and dependability are offered by new equipment but at a higher price. Secondly, used equipment can be much cheaper while having a good history but lacks some features and may need more maintenance.

This choice is vital for success in starting a brewery business as well as meeting goals and budgets.

Below is a simple comparison between the two types of equipments:

- New Equipment: high initial investment cost, current technology, warranty from manufacturer and low maintenance required.

- Used Equipment: low upfront costs, wear and tear possibilities, no warranty plus need for upgrades might arise.

Moreover, one should thoroughly inspect second hand machines considering long term operational costs too. Getting professionals involved could help you prevent future problems that come with this kind of decision-making process. At the same time knowing how it was used before could tell more about its condition now and how much longer will serve you.

3、Understanding Import Regulations and Logistics

While you import Chinese brewing equipment, it is important to know about the rules and logistics involved. They are the following cash deposit requirements that will be effective upon publication of the final results of this review for shipments of subject merchandise from China. Which means financial regulations may have to be complied with by importers which can affect the overall cost.

To make sure a successful importing process, take these steps into account:

- Check the HS Code(8438400000) for brewing machinery in order to specify import duties.

- Ensure whether or not they are being shipped in a standard wooden case so as not to damage them while on their way here.

- Confirm guaranteed delivery time and ask supplier’s commitment on shipping date exactness.

- Know what kind of support warranty does provider give? What happens after purchase service look like? This will help protect your investments.

It is vital that you work together with suppliers in terms of logistics like shipment or clearance through customs which would prevent any delay or ensure timely arrival of equipment. It involves engaging more deeply into planning stages so as much information can be shared thus making everything easier during imports.

Customizing Your Brewing Equipment

1、Designing Your Ideal Brewhouse

When it comes to opening a brewery that suits one’s needs, designing the perfect brewhouse is necessary. Customizing the system is important since this will not only work for any space available in your facility but also correspond with the manner in which you brew and utilities at hand. XG machinerys as well as Cassman are among those suppliers who have customized solutions so that every part of the brewing house can be optimized for use by different people according to their requirements.

Common equipment options for custom built breweries include:

- Three Vessel Brewery Equipment

- Four Vessel Brewery Systems

- Copper or Stainless Steel Mash Tuns

- Direct Fire, Electric or Steam heated Mashing Kettles

- Lauter Tun

- Whirlpool Tun

- Boiling Kettle

- Malt Milling Machine

All these units may be designed either for infusion mashing or decoction mashes by using materials such as stainless steel or red copper. Work platforms integration and heat exchanger selection are other aspects to consider when choosing them because they help improve hygiene during brewing procedure while increasing its efficiency respectively.

2、Integrating Control Systems for Automation

In the brewing world, automation changes everything. It allows for more control and consistency throughout the entire brewing process. From simple temperature controllers to complex PLCs (programmable logic controllers) with HMI (human-machine interface) touch screens – the control systems are what make this happen. Brewers are able to monitor vital signs like fermentation activity or temperature that need careful attention adjusted on each batch until it meets their specifications.

Everything from brewhouse tanks right down to brite beer tanks can be managed through one interface when using an automated control system at a brewery. This streamlines operations and greatly reduces potential human errors.

The following chart lists out some common parts found in a brewery’s typical control system:

Component | Function |

Temperature Controller | Manages tank temperatures |

PLC + HMI | Automates brewing process, offers touch screen control |

Solenoid Valves | Regulates flow of liquids |

CIP Systems | Automates cleaning of tanks |

Automated fermentation monitoring systems keep track of things like temperature, gravity, and other parameters which can all have big impacts quality-wise & efficiency-wise during any given brew day based solely off this real-time data alone; allowing brewers access to such valuable information so quickly means they’re better equipped for making decisions that will optimize their processes while still ensuring high-quality products.

3、Sourcing Auxiliary Equipment and Accessories

Accessories and auxiliary equipment have to be customized when setting up a brewery as they help in ensuring efficiency and quality. In fact, it is not only the main brewing system that should be chosen but also other components like glycol chillers, keg washers or grain mills.

Essentially, these are the necessary supplementary pieces:

- CIP (Clean-In-Place) Systems

- Keg Washers

- Grain Mills

- Pump Carts

- Yeast Brinks

- Glycol Chillers

- Lenticular Filters

Every item must fit into your current set-up flawlessly while meeting specific brewing requirements.

Furthermore do not underrate service & maintenance apparatus; regular service using appropriate tools can keep your brewery running longer by preventing downtimes. When evaluating different options one should look at warranties offered on products as well as how fast suppliers respond to inquiries for support services.

Maximizing Brewery Efficiency and Productivity

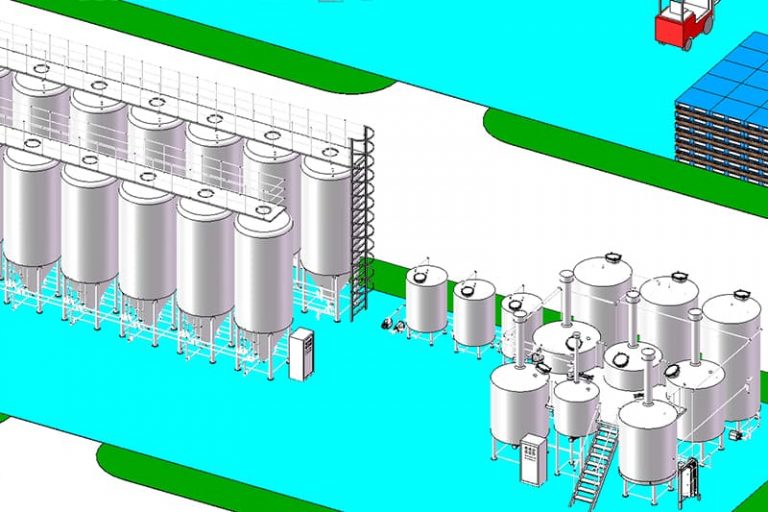

1、Optimizing Brewery Layout and Workflow

Efficient operation of a brewery relies on optimizing the layout and workflow. XG Machinery creates brewing systems that are specifically designed for your establishment so that each part fits perfectly well within the available space as well as matches with your brewing process. This customization also involves positioning equipment in such a way that it enhances smooth flow of activities which is necessary for daily routine and future productivity.

It is crucial to think about future expansion plans when coming up with a design for your brewery’s arrangement. We are experts in designing layouts that take into account equipment work flow, tap room space, regulatory requirements and growth prospects. By planning scalability from the beginning, you will be able to avoid expensive reconfigurations later on.

Below are some words used to describe this design:

- Brewing Water

- Brewery Service

- Brewery Starting

- Brewery System Design

- Brewery Machines Production

- Brewery Tank Shipping

- Brewery Equipment Installation

- Brewery System Running

- Beer Machine Maintenance

2、Maintenance and Upkeep of Equipment

If you want your Chinese brewing equipment to last longer and perform better, you need to keep it in shape with regular maintenance. This will ensure that the brewery remains productive and efficient, cutting down on costly repairs and downtime. To do this, establish a schedule of routine care that should include:

- Inspecting tanks and vessels for any dirt or rust

- Checking lubrication levels on movable parts like pumps

- Monitoring controls such as temperature gauges which may be out of calibration

It is important also to replace worn-out pieces when necessary. Besides troubleshooting aids, keeping an account of all activities done during servicing can help plan for future upkeep more effectively as well.

Moreover, many suppliers offer extensive post-installation assistance. For instance, XG Machinery provides continuous engineering support long after the warranty period expires so that your machines run smoothly. Take advantage of such services if you want your brewery to thrive!

3、Scaling Up: Expansion and Upgrading Strategies

When it is time to expand a brewery, there needs to be a strategic plan. The quality of craft beer should not be compromised by growth. This means planning carefully and investing smartly so that more can be made without losing what sets the brand apart.

- Review current production capacity and locate bottlenecks.

- Consider the advantages of adding new fermentation tanks or upgrading them.

- Look into automating certain processes in order to increase efficiency.

- Find out about different ways for extending distribution channels so as to reach more markets.

It is important when you are upgrading your brewery equipment that you understand where things are now and what they might become later. This will allow for better brewing ability which meets demands placed on it currently as well as those expected going forward with increased production levels being reached due largely because people want more craft beers than ever before.

Remember that long term running costs come along with buying new machinery – not just initial purchase but also ongoing maintenance & energy usage too; these factors affect profitability in breweries greatly therefore need consideration during selection process amongst others such as detailed cost-benefit analysis to help choose right investment improvements likely provide higher returns over time.

Leveraging Support and Services

1、Utilizing After-Sales Services

When investing in Chinese brewing equipment, there is more to be done than just the purchase. A responsive customer support system and after-sales service must be present behind a reliable brewing system. This will help ensure that any problems experienced after installation are dealt with quickly so as not to interrupt production.

After-sales services may vary greatly from one supplier to another but are likely to include:

- Warranty period for tanks and other equipment

- Technical support and troubleshooting

- Free on-site guidance on installation and debugging by professional brewing engineers

- Training in beer brewing technology and provision of brewing formulas

- Supply of beer brewing raw materials

To keep your brewery running smoothly, it’s important to have post-installation support that covers all bases. With this kind of service provided even after the warranty has expired; you can concentrate on making great brews instead of worrying about breakdowns in machinery.

2、Engaging in Training and Consultation

Making your brewery successful involves training and consulting. The learning period may be reduced by seeking professional advice which also helps in avoiding common errors. Most suppliers offer training programs that are comprehensive covering everything ranging from operation of equipment to advanced brewing methods.

For example Fermentis Academy has a variety of educational resources like webinars and expert insights that are customized for the beverage industry.

Moreover, going to trade shows and exhibitions allows one to interact directly with experts in the field as well as get hands-on experience with new products. Some services which can be found at such events include:

- Beverage tastings

- Fermentation solutions

- Beer styles and brewing insights

- Active dry yeast and bacteria information

- Fermentation aids and functional products access

It is important to know that better beer quality could be achieved through education thus time should be invested in it alongside consultation leading to increased efficiency within processes hence more success for the brewery in general.

3、Exploring Financing Options for Brewery Investments

Although it is not easy to find the necessary capital for brewery investments, there are many financial options to choose from. The first thing you need to do is understand them. You can consider traditional bank loans, investors or even specialized brewery financing companies as growth financing options for craft breweries.

Before making any decision on what type of loan you will go for when looking at how to finance a startup brewery, always ensure that terms and conditions are favorable enough for your business’ growth. Here are some common financing methods that might be suitable for your situation:

- SBA Loans – these government backed loans have good terms and rates.

- Business Loans – these can be customized by banks or other financial institutions.

- Equipment Leasing – instead of buying equipment outright this option allows one to free up cash flow.

- Crowdfunding – this is where small amounts of money are raised from a large number of people usually through the internet.

The lenders and investors also require a good business plan with financial projections showing profitability in order to grant you the funds needed. The best way of ensuring this is having a well thought out strategy in place which clearly defines how every cent borrowed will be utilized towards achieving success in the brewing industry.

Lastly, working capital solutions should never be underestimated as they help smoothen cash flows thereby enabling better investment decisions around brewery growth.

Conclusion

In the end, whether a brewer is just starting out or an old hand, it may be thought to buy Chinese brewing systems. You can get everything you want with this kind of equipment: they range in size from small pilot kits all the way up to full-scale commercial breweries; YoLong Brewtech offers design services as well as manufacturing, shipping/installation/financing packages that could be described as more like turnkey operations than anything else. But what should someone keep in mind before clicking “add to cart”? The type of system being considered; how much beer is expected (or desired) to come out per batch; and any unique ingredients / methods required by recipe formulation need into consideration prior too purchasing anything! With enough research, consultation with experts and methodical planning around infrastructure development there’s no doubt one will eventually land themselves onto perfect investment which will serve them greatly over long time spans – always remember stay current within craft beer world trends so that business stays competitive amidst other players.

FAQ

- What types of Chinese brewing equipment are available for purchase?

To purchase Chinese brewing equipment, pilot brewing kits, microbrewery systems, nano brewery equipment, commercial brewery systems, winery equipment and other auxiliary devices such as fermenters brite tanks CIP stations control system etc., are available in the market for sale.

- How can I assess the quality and specifications of Chinese brewing equipment?

To determine if a piece of Chinese brewing equipment has good quality or meets certain requirements; check certifications; look at materials used; consider technological advancement shown by it vis-a-vis others in its category; see what customers say about them – their feedback might reveal areas where improvements can be made so as to satisfy international standards for producing drinks abroad.

- What should I consider when choosing between new and used Chinese brewing equipment?

Budget is one factor but also think about warranty coverage terms which may vary greatly depending on where you buy from; another thing worth considering would be checking previous usage records because this will give insight into how often these things need repairs done – hence maintenance history matters too. The most important factor however would be whether any given machine meets current production needs as well future expectations based upon projected growth levels within company.

- What are the import regulations and logistics involved in purchasing brewing equipment from China?

If you want to know about the customs duties levied on imported beer-making machinery manufactured overseas then shipped into our country through various ports nationwide such as New York City harbor which happens quite often due its location along major waterways connecting Atlantic Ocean with Great Lakes region via St. Lawrence seaway system etcetera.

- How can I customize my Chinese brewing equipment to fit my specific needs?

You could customize your Chinese brewing equipment by coming up with brewhouse layouts together with the supplier, automating control systems and choosing tanks as well as filtration systems that match your brewing process and capacity needs.

- What after-sales services and support can I expect when purchasing Chinese brewing equipment?

Once you have bought Chinese brewing equipment, they will offer installation help; provide technical training; give maintenance tips; supply spare parts; finance your brewery investment.

After-sales service

- Be specific and go into as much detail as you can about everything!

- Don’t write off ideas or suggestions that they have, some are good and can be better than what you have seen before.

- Go through everything carefully, and then try to do it again.

- Visit the factory during production and be involved with the process as much as you can.

- Stay in regular contact with the supplier.

- Get spares and most of them. Spare seals, elements, everything you can think of, and more than you think you’ll need. Having a critical spare in stock could be the difference between brewing and not brewing for weeks.

- Build-in redundancies. For example, we designed the pipework of the brewhouse so that both pumps can do any task. If one breaks, the brewmaster can still brew using the other.

- Reference projects could help you a lot. You could learn what you want to know about a supplier, the quality, the service, what is more, some brewing comments based on their brewery equipment.

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive

Fermentation Tanks The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose the most suitable fermentation

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive

Fermentation Tanks The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose the most suitable fermentation