The main raw materials of beer are barley malt and wheat malt. Hops added during brewing to enhance the taste of the beer. Because the production materials and brewing process of beer are different. So it can divide into industrial beer and craft beer. So what is the difference between industrial beer and craft beer?

Differences between craft beer and industrial beer

Different brewing ingredients

Craft beer uses only malt, hops, yeast, and water for brewing. No artificial additives added. Compared with industrial beer, it has more malt content and more hops. So, the brewed wort has a higher concentration.

Industrial beer is also brewed using malt, hops, yeast, and water. But sometimes in pursuit of cost, raw materials such as rice, corn, and starch used instead of malt. The beer brewed in this way has a very low wort concentration and a light taste.

Industrial beer is also brewed using malt, hops, yeast, and water. But sometimes in pursuit of cost, raw materials such as rice, corn, and starch used instead of malt. The beer brewed in this way has a very low wort concentration and a light taste.

Different fermentation time

Because craft beer does not need to worry about the cost too much. So, the fermentation time does not consider the time cost. The fermentation time of the most traditional craft beer can be as long as 2 months. In this beer fermented, the wort concentration is higher, and the flavor is stronger.

For industrial beer, time is money. So, the fermentation time of industrial beer is usually only about 7 days. Such beer fermentation will not be particularly enough. So, the concentration of wort is low and the flavor is lighter.

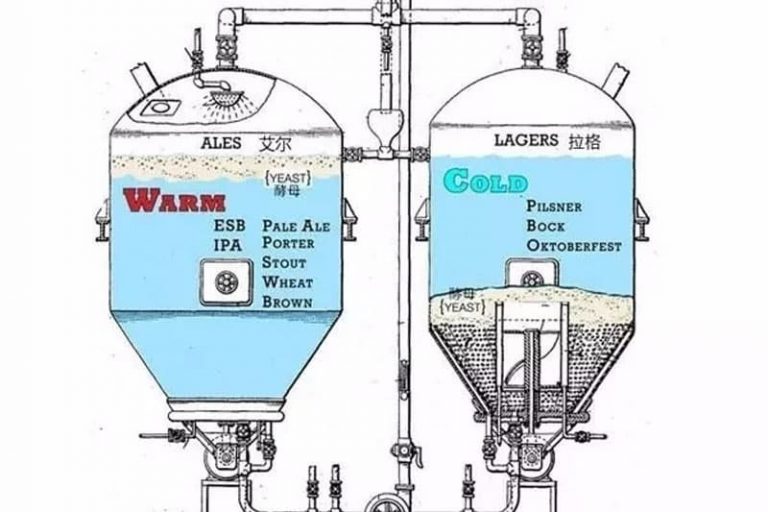

Different fermentation process

The fermentation process of craft beer and ordinary industrial beer is also different. Craft beer uses the Ales process (upper fermentation process). Industrial beer uses the Larges process (lower fermentation process). The difference between these two processes is the location of the yeast during the fermentation process. Of course, the fermentation temperature is also different.

Most craft beer uses the Ales process. Yeast works at the top of the fermentation tank, floating above the liquor. The fermentation temperature is generally controlled at 10-20°C. Fermentation tanks are usually small. After the fermentation, there is no need to filter and sterilize.

Most of the industrial beer uses the Lagers process. Yeast works at the bottom of the fermentation tank, sinking under the liquor. The fermentation temperature is generally controlled below 10°C. The fermentation tank is larger. After fermentation, filtration and pasteurization are usually used. This is to increase the shelf life (shelf life) of beer.

The storage time is different

Craft beer and ordinary industrial beer are different in storage method and time.

Because most craft beer is not filtered and sterilized. So, craft beer is not very resistant to preservation. Most craft beer has a short shelf life, and some have a shelf life of only ten days.

After fermentation, industrial beer will filter and pasteurized, with a longer shelf life. The shelf life of general industrial beer is 1-2 years, and some can even be as long as decades.

Because most craft beer is not filtered and sterilized. So, craft beer is not very resistant to preservation. Most craft beer has a short shelf life, and some have a shelf life of only ten days.

After fermentation, industrial beer will filter and pasteurized, with a longer shelf life. The shelf life of general industrial beer is 1-2 years, and some can even be as long as decades.

Different beer output

Craft beer emphasizes diversification, miniaturization, quality, and localization. Almost all craft breweries must have been microbrewery when they started. Also, many wineries can only be microbrewery forever because of their own specialization. In the United States, the government requires craft brewery not to controlled by the industrial brewery. Or, the share of the industrial brewery must not exceed 25%.

Craft beer requires low yield, takes the route of high-quality products, and is full of characteristics. The United States requires craft breweries to produce no more than 6 million barrels per year.

The annual output of industrial beer is often ten or several times that of a craft brewery. This kind of ultra-large-scale production must reduce its own taste requirements. Because the beer produced by industrial breweries needs to meet most people’s tastes. So the taste is very light.

Different style and nutritional value

There are big differences between craft beer and industrial beer because of the brewing process and raw materials. So, the brewed style and nutritional value are also quite different.

Generally, craft beer adds more types and quantities of malt, yeast, and hops. So, a variety of different flavors of beer can brew. For example, the aroma of wheat beer, heavy dark beer, amber beer, and fruit beer. There are 100 styles of craft beer in the world divided by type. These craft beers all have a strong aroma, high content of the wort, and a thick and full taste. So the price of nutrition is higher. But the price will be higher. The alcohol content of craft beer is more than 11 degrees, and the precision of some craft beer can reach 20 degrees.

Industrial beer has a uniform taste. Because of the single brewing process and style of industrial beer, the fermentation time is short. So, industrial beer has the characteristics of light taste, more bubbles, and low wort concentration. Of course, low hop content and low alcohol are also characteristics of industrial beer. Also, the nutritional value and price of industrial beer will be lower.

Generally, craft beer adds more types and quantities of malt, yeast, and hops. So, a variety of different flavors of beer can brew. For example, the aroma of wheat beer, heavy dark beer, amber beer, and fruit beer. There are 100 styles of craft beer in the world divided by type. These craft beers all have a strong aroma, high content of the wort, and a thick and full taste. So the price of nutrition is higher. But the price will be higher. The alcohol content of craft beer is more than 11 degrees, and the precision of some craft beer can reach 20 degrees.

Industrial beer has a uniform taste. Because of the single brewing process and style of industrial beer, the fermentation time is short. So, industrial beer has the characteristics of light taste, more bubbles, and low wort concentration. Of course, low hop content and low alcohol are also characteristics of industrial beer. Also, the nutritional value and price of industrial beer will be lower.

Different ways of drinking

Because of the taste, it is more particular when drinking craft beer. Industrial beer is not so particular.

Craft beer usually has a richer taste and high alcohol content, which is suitable for slow tasting.

Industrial beer usually has a lighter taste and low alcohol content, making it suitable for large mouthfuls.

Craft beer usually has a richer taste and high alcohol content, which is suitable for slow tasting.

Industrial beer usually has a lighter taste and low alcohol content, making it suitable for large mouthfuls.

Different development history

The fermentation history of craft beer is longer than that of industrial beer. Craft beer has already appeared before industrial beer.

In the beginning, Ayer beer (craft beer) produced by women. This is to protect their families from surviving in harsh environments (such as plague, famine, polluted water sources, etc.). In the Middle Ages, a large number of people died of the plague, and the church took over the production of beer. Because the market demand for beer has soared, profits are also high. So, craft beer has developed. At that time, many European royal families also established their own royal breweries to brew craft beer. Because of the emergence of refrigeration equipment. So, an industrial beer with stable quality, non-perishable, and suitable for transportation became popular. Also, because of the development of glass products. So, the turbid Al beer is not very popular. People like lagers beer (industrial beer).

In the 1840s, beer brewers in Bavaria, Germany brought beer fermentation technology to Pilsen, Czech Republic. He produced the world’s earliest golden beer-Pilsner beer (industrial beer). Because of the emergence of refrigeration equipment. This beer, which is stable in quality and hard to deteriorate, is suitable for large-scale industrial production and transportation. Also, with the advancement of transportation methods, Pilsner beer and Pilsner brewing have become popular throughout Central Europe. Later, European beer brought to the United States by immigrants. Americans also like this beer. But, because there is less barley in the United States, corn used instead of barley for brewing beer. Later, it evolved into beer brewing with rice or starch instead of barley. In the end, it formed the American industrial beer that is now on the market.

In the beginning, Ayer beer (craft beer) produced by women. This is to protect their families from surviving in harsh environments (such as plague, famine, polluted water sources, etc.). In the Middle Ages, a large number of people died of the plague, and the church took over the production of beer. Because the market demand for beer has soared, profits are also high. So, craft beer has developed. At that time, many European royal families also established their own royal breweries to brew craft beer. Because of the emergence of refrigeration equipment. So, an industrial beer with stable quality, non-perishable, and suitable for transportation became popular. Also, because of the development of glass products. So, the turbid Al beer is not very popular. People like lagers beer (industrial beer).

In the 1840s, beer brewers in Bavaria, Germany brought beer fermentation technology to Pilsen, Czech Republic. He produced the world’s earliest golden beer-Pilsner beer (industrial beer). Because of the emergence of refrigeration equipment. This beer, which is stable in quality and hard to deteriorate, is suitable for large-scale industrial production and transportation. Also, with the advancement of transportation methods, Pilsner beer and Pilsner brewing have become popular throughout Central Europe. Later, European beer brought to the United States by immigrants. Americans also like this beer. But, because there is less barley in the United States, corn used instead of barley for brewing beer. Later, it evolved into beer brewing with rice or starch instead of barley. In the end, it formed the American industrial beer that is now on the market.

This is the difference between industrial beer and craft beer. If you are fed up with industrial beer and are ready to brew your own craft beer, please contact us. We will provide you with a turnkey solution for brewery equipment. Moreover, we have professional brewers to help you complete your craft beer.

Get a turnkey solution for brewery equipment

If you plan to open or expand the brewery, you can contact Micet Craft directly. Our engineers will design and manufacture brewery equipment according to your brewing process. Of course, we will also provide you with a complete turnkey solution. Also, if you plan to expand the brewery, we will provide you with customized solutions.