How big is your brewery?

Where is the location of the brewery?

Where are you going to purchase your brewing equipment?

- Brewhouse (for example mash mixer, lauter, and brew kettle/whirlpool)

- Malt Mill

- Heat Exchanger

- Heating System

- Fermentation Tank

- Bright Beer Tanks (BBT’s)

- Glycol System for Beer Cooling

- Cold Water Tank (optional)

- Hot Water Tank

- Keg Cleaner

- CIP Unit (optional for smaller breweries)

- Movable pump

- Yeast Brink (optional)

- Beer Hose

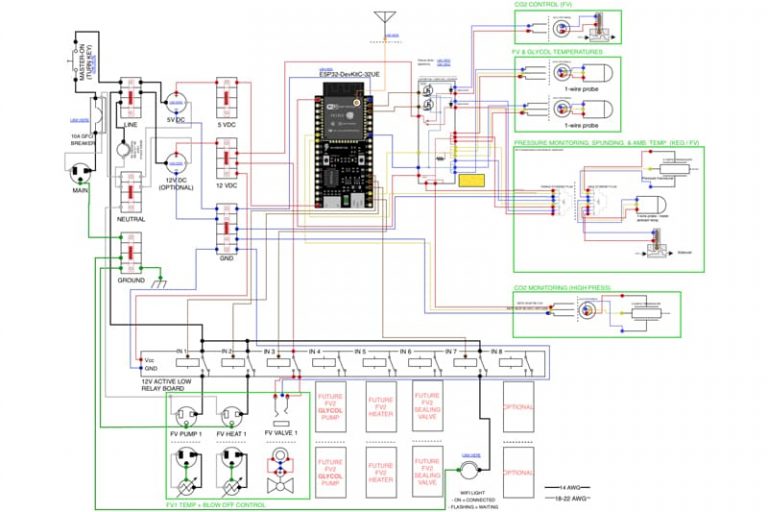

- Control panels

- Cables and piping

- Packaging line (bottle or cans)

What container do you plan to put the beer in?

What type of brewery equipment do you want to buy? (Manual/automatic or between)

- Time-saving (up to only 20 minutes instead of 5-7 hours)

- Full automation (does the steps automatically)

- Less room for errors

- Automatic documentation

- Easy to tweak and perfect recipes

- Avoid waiting times

- Cleaning convenient

- Requires less labor

High upfront cost

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza, desde pequeños lotes de equipos de elaboración de microcerveza hasta 100 barriles de capacidad. Micet Craft ha alcanzado la cooperación con muchas fábricas de cerveza de todo el mundo, podemos

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de elaboración de cerveza. Proporcionamos a los clientes soluciones de cervecería llave en mano, que incluyen el diseño, la fabricación y la instalación de cervecerías personalizadas. El equipo de Micet Craft

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque brite. El tanque brillante es una parte importante del flujo de trabajo de los cerveceros profesionales. Puede usarse para almacenar y carbonatar cerveza, eliminando así la molestia de limpiar barriles