During fermentation, the wort sugars are consumed and new yeast cells are formed along with ethanol and carbon dioxide, while producing flavor compounds. As brewers, we control various elements of fermentation to produce finished beer on schedule.

- The key elements are:

- Temperature

- lOxygen level

- lPitching rate

- Yeast selection

They all affect the aroma and flavor compounds produced during fermentation.

Beer fermentation stage - lag stage

yeast

fermentation temperature

Good timing on the fermentation temperature. The style of beer you choose to brew, as well as the yeast you use, will determine the fermentation temperature.

- Ale: 62-75 °F (17-24 °C)

- lLager: 46-58 °F (8-14 °C) *Note: Lager fermentation can begin at elevated temperature (~60 °F/15.5 °C) until signs of fermentation (gravity drop, CO₂ production, head part formation) is obvious. Once symptoms of fermentation are observed, cool to desired fermentation temperature.

- Wheat and Belgian styles: 62-85 °F (17-29 °C)

Beer fermentation stage - active stage

Depending on the beer style, visual activity will begin to be seen within 24-48 hours of pitching. Yeast is coming out of the lag phase and into the anaerobic phase. The lag period can be as short as 30 minutes.

Yeast cell counts increase during the active phase. Yeast starts to consume the sugar made on brewing day. Carbon dioxide is produced and a layer of foam can be seen.

As the number of cells increases, ethanol and flavor compounds are produced. At this point you can smell the fermentation. If neutral yeast is used, such as Fermentis US-05, it may smell like olive oil.

Activity at this stage is temperature dependent, and the higher the temperature, the more active the activity. Yeast consumes sugar in a certain pattern. Monosaccharides are first consumed with glucose, followed by fructose and sucrose, before entering metabolism. The glucose content in a typical beer wort is about 14% of all sugars.

maltose

The main sugar and the heart of the brew is maltose, which is an important flavor ingredient. Maltose makes up 59% of the wort sugar in a typical beer. Maltose is used by yeast to impart properties to beer that many brewers have planned in formulation development. When fermentation is at its most active, the foam at the top of the wort usually turns from yellow to brown. Brown spots made of oxidized hop resin can also be seen.

fermentation temperature

Lagers – For some strains of lager, brewers increase the fermentation temperature after 50 to 60% fermentation. They allow the beer to «free rise» and the temperature can be as high as 20°C (68°F). The elevated temperature will make the beer «self-purify», reducing the rate of diacetyl.

- Cool down to 10°C (50°F) and hold at this temperature for 48 hours

- Cool to 5°C (41°F) and hold at this temperature for 24 hours

- Cool to 0 to 3°C (32°F), the temperature maintained for ripening.

Beer fermentation stage - static stage

During the fermentation stage after most of the sugar in the wort is consumed, the fermentation rate drops sharply. During this period, most of the final sugars are consumed and some secondary metabolites are converted by yeast. As the alcohol content increases and sugar and nutrients are depleted, the yeast begins to flocculate and settle.

Yeast growth slows as the beer enters a stationary phase. Most flavor and aroma compounds have already been produced. These include fusel alcohols, esters, and sulfur compounds. During the resting phase, the beer is conditioned. Yeast reabsorbs diacetyl produced during fermentation. Hydrogen sulfide escapes from the fermenter as a gas. The attenuation level is checked by measuring the specific gravity of the wort.

- Reduce the production rate of ethanol and carbon dioxide

- Diacetyl conversion

- Reduction of some flavor compounds through yeast metabolism or carbon dioxide scrubbing

- Reach terminal gravity

- Yeast flocculation and sedimentation start

fermentation temperature

- Ales: same as primary fermentation (higher temperature increases diacetyl reduction rate)

- Lager: 40-60 °F (4-15 °C). Some brewers allow the temperature of the beer to be elevated to speed up the reduction of diacetyl. This elevated temperature usually only lasts 24 to 48 hours.

- Wheat and Belgian beers: same as primary fermentation (higher temperature increases diacetyl reduction rate).

If the brewery’s next step is to re-ferment the yeast, the brewery will first confirm that the quality of the harvested slurry has reached certain standards of viability and purity by the end of the secondary fermentation. Since these methods are beyond the scope of most homebrew needs, there are some simple techniques to help determine whether re-extracting yeast from homebrew is a good option.

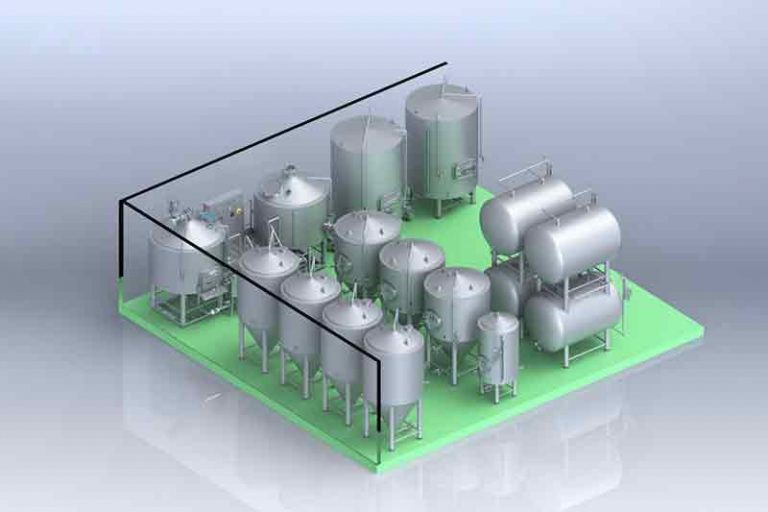

The Turnkey Way to Start Home Brewing

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza, desde pequeños lotes de equipos de elaboración de microcerveza hasta 100 barriles de capacidad. Micet Craft ha alcanzado la cooperación con muchas fábricas de cerveza de todo el mundo, podemos

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de elaboración de cerveza. Proporcionamos a los clientes soluciones de cervecería llave en mano, que incluyen el diseño, la fabricación y la instalación de cervecerías personalizadas. El equipo de Micet Craft

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque brite. El tanque brillante es una parte importante del flujo de trabajo de los cerveceros profesionales. Puede usarse para almacenar y carbonatar cerveza, eliminando así la molestia de limpiar barriles

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China. Producimos principalmente sistemas de elaboración de cerveza llave en mano personalizados de alta gama. Ya sea que esté planeando abrir una nanocervecería, una microcervecería o una cervecería comercial, podemos brindarle

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro sistema de llenado de cerveza utiliza acero inoxidable como material de producción. El acero inoxidable no es fácil de usar y es fácil de limpiar. Micet Craft le ofrece una

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza, desde pequeños lotes de equipos de elaboración de microcerveza hasta 100 barriles de capacidad. Micet Craft ha alcanzado la cooperación con muchas fábricas de cerveza de todo el mundo, podemos

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de elaboración de cerveza. Proporcionamos a los clientes soluciones de cervecería llave en mano, que incluyen el diseño, la fabricación y la instalación de cervecerías personalizadas. El equipo de Micet Craft

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque brite. El tanque brillante es una parte importante del flujo de trabajo de los cerveceros profesionales. Puede usarse para almacenar y carbonatar cerveza, eliminando así la molestia de limpiar barriles

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China. Producimos principalmente sistemas de elaboración de cerveza llave en mano personalizados de alta gama. Ya sea que esté planeando abrir una nanocervecería, una microcervecería o una cervecería comercial, podemos brindarle

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro sistema de llenado de cerveza utiliza acero inoxidable como material de producción. El acero inoxidable no es fácil de usar y es fácil de limpiar. Micet Craft le ofrece una