Boiling time

boiling strength

(1)preheat:Start preheating after the filtered wort has passed the heater surface (or heating belt), and the amount of steam now is smaller. The purpose of the preheating process is to prevent the temperature of the wort from cooling down during the filtration period so that the temperature will drop. Or preheat with hot water through a thin plate heat exchanger.

(2)initial boiling:The wort is near the early stage of boiling, and the initial boiling time should not exceed 30 minutes. The steam volume at this stage has not been opened, and the steam volume is not very large. The tank washing process is still going on in preparation for evaporation. Once the tank is washed, it can immediately enter the boiling evaporation stage.

(3)boiled:The amount of steam at this stage is opened to the most so that the wort is kept boiling . The quality of boiling has a significant effect on the coolness and settable nitrogen content of the wort.

Changes during wort boiling

Dissolution and Transformation of Hop Bitterness

Formation and isolation of coagulable protein-polyphenol complexes

Evaporate excess water so that the wort reaches the specified concentration

Sterilize the wort

Completely destroy enzyme activity and fix wort components

Wort color rise

Increased wort acidity

Formation of reducing substances

Changes in Dimethyl Sulfide (DMS) Content in Wort

Craft Beer Equipment Boiler

- heated boiling pot

- Jacketed steam boiler

- Electric heating tube boiling pot

- Boiling pot with a built-in heater

Saccharification pot heating form

Electric heater heating: The initial investment cost of electric heating equipment is low, the operation is simple and easy to learn, and it is suitable for small beer brewing equipment 100L-500L; Many heaters can be controlled , which is convenient to control the overflow when boiling.

Burner direct fire heating: Direct fire heating equipment is a traditional heating method. A separate combustion chamber is configured at the bottom of the boiling pot as a heating area, and burners are used for heating. Direct fire heating generally requires a stirring device to prevent the pot from sticking. Generally, burners The power can be adjusted within a certain range, and it is very important to choose a burner with appropriate power. It is one of the preferred choices for customers in the Americas.

Steam heating method: The heating effect of steam heating is more stable, and the beer tastes good. The area and position of the jacket should consider the boiling requirements. Consider the independent control of the bottom jacket and the barrel jacket, or even consider dividing the barrel jacket into two. It is convenient to adjust the boiling intensity and use different jackets during mashing. At the same time, the bottom jacket can be used alone to heat the wort when there is little wort, saving the wort boiling time.

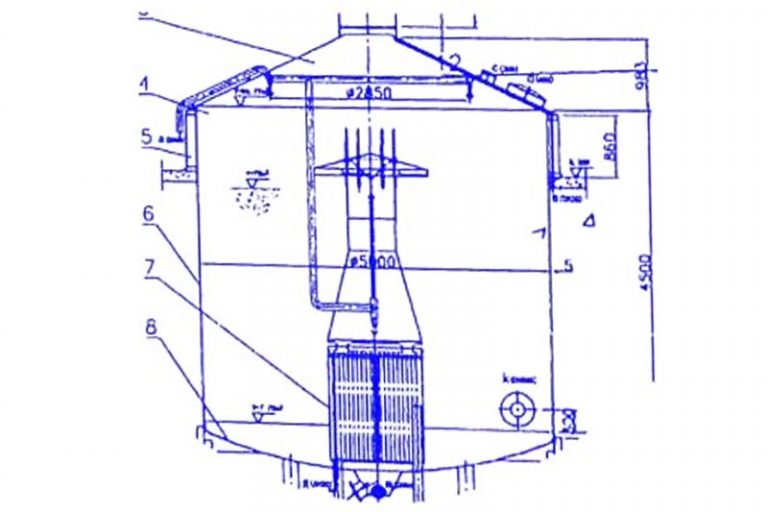

Internal heater type: When the wort is boiled, the wort is heated and boiled upward through the tubes of the heater from bottom to top. An umbrella-shaped overflow prevention cover is installed above the heater, so that the rising wort can be distributed to the surrounding, and at the same time, the formation of foam can be avoided, and the wort can be heated .

Get a turnkey solution for craft brewery equipment

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza, desde pequeños lotes de equipos de elaboración de microcerveza hasta 100 barriles de capacidad. Micet Craft ha alcanzado la cooperación con muchas fábricas de cerveza de todo el mundo, podemos

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de elaboración de cerveza. Proporcionamos a los clientes soluciones de cervecería llave en mano, que incluyen el diseño, la fabricación y la instalación de cervecerías personalizadas. El equipo de Micet Craft

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque brite. El tanque brillante es una parte importante del flujo de trabajo de los cerveceros profesionales. Puede usarse para almacenar y carbonatar cerveza, eliminando así la molestia de limpiar barriles

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China. Producimos principalmente sistemas de elaboración de cerveza llave en mano personalizados de alta gama. Ya sea que esté planeando abrir una nanocervecería, una microcervecería o una cervecería comercial, podemos brindarle

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro sistema de llenado de cerveza utiliza acero inoxidable como material de producción. El acero inoxidable no es fácil de usar y es fácil de limpiar. Micet Craft le ofrece una

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza, desde pequeños lotes de equipos de elaboración de microcerveza hasta 100 barriles de capacidad. Micet Craft ha alcanzado la cooperación con muchas fábricas de cerveza de todo el mundo, podemos

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de elaboración de cerveza. Proporcionamos a los clientes soluciones de cervecería llave en mano, que incluyen el diseño, la fabricación y la instalación de cervecerías personalizadas. El equipo de Micet Craft

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque brite. El tanque brillante es una parte importante del flujo de trabajo de los cerveceros profesionales. Puede usarse para almacenar y carbonatar cerveza, eliminando así la molestia de limpiar barriles

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China. Producimos principalmente sistemas de elaboración de cerveza llave en mano personalizados de alta gama. Ya sea que esté planeando abrir una nanocervecería, una microcervecería o una cervecería comercial, podemos brindarle

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro sistema de llenado de cerveza utiliza acero inoxidable como material de producción. El acero inoxidable no es fácil de usar y es fácil de limpiar. Micet Craft le ofrece una