Today I decided to write an article about using a cold liquor tank (CLT) to cool wort. This is because our customers are always wondering whether or not to use CLT to cool wort. To let more winemakers understand the advantages and disadvantages of using CLT to cool down, the engineers of Micet Craft decided to write this article.

Use cold liquor tank to cool wort

What is a cold liquor tank (CLT)?

CLT is a short-term cold liquid tank, which is used to store cold water in your beer container. CLT is used to cool the wort from the plate heat exchanger to the fermentation tank. Of course, the cold liquid tank can also receive cold water from the plate heat exchanger. The tank is usually stainless steel and is placed near the brewhouse equipment, preferably next to the heat exchanger.

The cold liquid tank is welded with a cooling jacket, which means that it has an inner shell and an outer shell, and an insulating material is filled between the inner shell and the outer shell. Between this shell is a coil, which allows the glycol in your cooling system to pass through it, allowing you to cool the water in the tank to the required temperature.

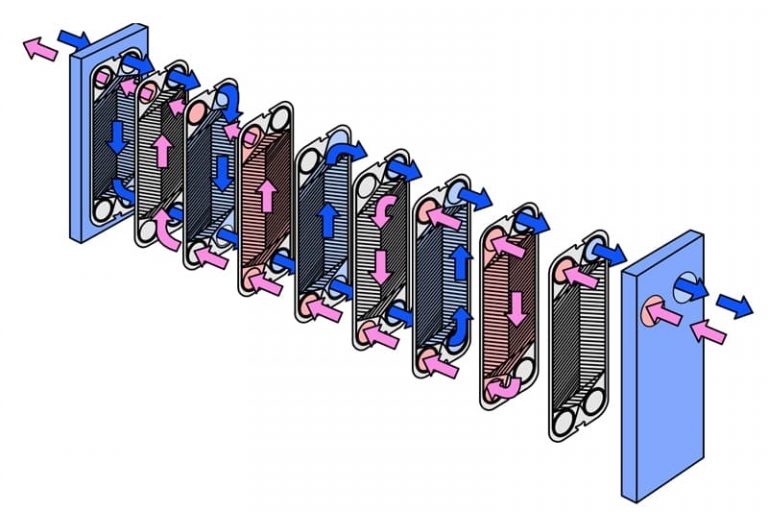

You can cool the water to 1°C~7°C, depending on the beer style being brewed. The water in the CLT is pumped through a heat exchanger to cool the wort that enters the FV. When cold water passes through one side of the heat exchanger, the hot wort passes through the other side, allowing the wort to cool down quickly. This means that it will immediately cool down to the temperature required for fermentation. The water will not come into contact with the beer but will enter the hot liquid tank (HLT). The cold water « takes away » the heat from the beer and heats itself. This hot water can be used for the next brewing or to clean the brewery equipment.

Advantages of using CLT to cool wort

Let us first understand the advantages of using CLT to cool wort:

Water that always maintains the required temperature

When using city/tap water to cool wort, the temperature of the water may be affected by temperature changes throughout the year. Tap water in summer maybe 12-20°C higher than at other times of the year. For lager (or even ale), it may be difficult to adjust the wort to the required temperature. This means that the ethylene glycol in your two-stage heat exchanger works more efficiently, resulting in a higher temperature of the ethylene glycol at the end of the wort collection. In addition, you may need to turn off FVs in the cellar that is in a cold state, otherwise, they may also become hot.

In addition, please note that the ambient temperature in summer is also relatively high, and the entire glycol system must work harder to restore the glycol temperature to normal operating levels. During these summer months, you did put a lot of pressure on the glycol system. Because the ambient temperature is relatively high, it needs to work harder anyway.

However, the above-mentioned is not a problem for the equipment using CLT. When the water in the CLT flows out, the temperature will remain the same throughout the collection process from wort to FV. If you use city water for cooling, you need to always pay attention to the overall temperature of the wort entering the FV, and the temperature of the cold water using CLT is constant, which is reassuring. You simply need to remember to recirculate the CLT before wort cooling so, there’s an even temperature throughout your tank.

Have more hot water for cleaning or next brewing

When you use cold water to cool the wort, you will produce a lot of hot water, which can be used for subsequent brewing or cleaning. For example, I like to clean my keg the day after the brewing day, and I will provide sufficient hot water for this work. In addition, if you decide to make proper caustic soda brewing the next day, you also have enough hot water to complete this task. Where using a single-stage water tank comes into its own, is doing back-to-back brewing. Please note, the hot water created from the wort collection can be used to conduct the next brew.

Reduce the workload of the glycol cooling system

Using a single-stage cold water heat exchanger means that you do not need to use glycol to cool the wort. Therefore, it has lower requirements for the glycol system, and you do not have to turn off the cooling of the cellar tank that is already in a cold state. Another advantage includes that a glycol system of a specific size can now cool more wine cellars. Therefore, more storage tanks can be added during installation or later expansion.

Of course, you use ethylene glycol to cool the water in the CLT, but this is a slower process that takes about 24 hours. Unlike the use of glycol to cool wort, it does not overload the glycol system.

Disadvantages of using CLT to cool wort

As mentioned above, having a dedicated CLT will increase the additional cost of piping and control devices, and the insertion of the tank into the glycol cooling system will also require payment. But it is well known that the cost of heating water is high. Over time, you can recover the original cost, and the recovered hot water can be used for other tasks. If you brew continuously, each brew will provide hot water for subsequent brewing.

Space

CLT will take up more space. If you are a brewpub, space is very precious. If the use of CLT will cost you a table or two, then it may not be the best choice.

Planning

When you use CLT, you need to add water at least 24 hours before the brewing day and start cooling. Why does it need to be 24 hours in advance? This is because it takes time to cool the water.

In addition, if there is no relatively large water pressure, it may take time to fill the tank. Also, when you fill the water tank, you may not be able to use water elsewhere. This means that you need to plan this action separately in your schedule.

How much CLT do you need?

How much CLT you need depends on the size of your brewhouse and the style of beer you need to brew. If you need to brew lager beer, because the fermentation temperature of lager beer is lower than that of ale beer, you need a larger CLT. A suitable heat exchanger can cool 5.5°C (10°F) with 1.3L of cooling water for every 1L of wort. In addition, if you need continuous brewing, it is also recommended that you use a larger CLT.

Under normal circumstances, brewery equipment manufacturers and brewing consultants will recommend the use of twice the brewing capacity of CLT. Therefore, if you have a 2000L brewhouse, it is recommended to use a 4000L CLT. This is because a larger CLT can provide you with a buffer and can cool down the wort easily. However, if your brewhouse needs to brew several batches a day, we would recommend that you use a CLT with three times the brewing capacity.

Alternatives to CLT

When you buy brewhouse equipment, many brewery equipment manufacturers will not provide CLT. Instead, they have a two-stage heat exchanger (HX). Level 2 HX will use tap water/city tax for the first level of cooling and then enter the hydrothermal tank. It also uses glycol from the cooling system to cool the wort in a second stage. Therefore, we say that the use of tap water and ethylene glycol to cool is two cooling stages.

The advantage of this system is that your brewhouse is one less jar. If you have limited funds or do not have much space, it may be the first choice. However, as a manufacturer with many years of experience in the production of brewery equipment, we always recommend that customers use CLT as much as possible. Let us see why.

Now, we have discussed a lot about the advantages and disadvantages of owning CLT. As you know, if space and budget permit, we recommend that you use CLT. It is good value for money and will make your brewing plan easier.

It is useful to be able to use this cold water to make hot water, especially when brewing multiple times a day. The most important thing is that it means less work for your glycol cooling system, so there is no pressure when trying to cool the hot wort. If you are still unsure and want to continue the discussion with us, you can leave a message to us below.

Get a turnkey solution for craft breweries

If you are ready to open a craft brewery, you can contact us. Micet Craft’s engineers will provide you with a list of craft brewery equipment and related prices. Of course, we can also provide you with professional turnkey brewery solutions, allowing you more time to focus on brewing delicious beer. Micet Craft very much hope to cooperate with you, my friend!