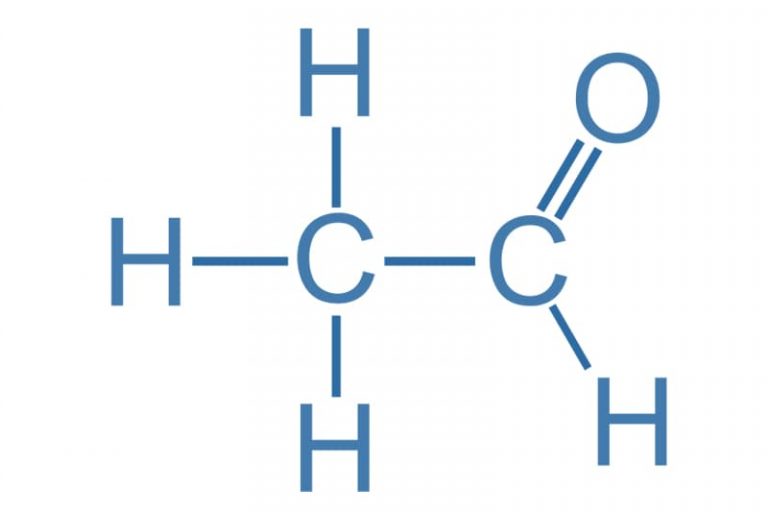

What is acetaldehyde?

Why is acetaldehyde produced?

- The beer is not fully fermented;

- Yeast strains are unhealthy and have poor performance;

- Excessive oxidation reaction occurs, allowing ethanol to be oxidized to acetaldehyde. This usually happens during the bottling process;

- What strain of yeast are you using? Some yeast strains produce more fermentation by-products than other yeast strains. Also, some yeast strains flocculate before completing fermentation, resulting in incomplete fermentation and production of acetaldehyde.

- Did you make a yeast starter? A smaller number of yeast strains puts pressure on the yeast, which means that they produce more acetaldehyde during the growth phase of their life cycle.

- At what temperature do you ferment? The low temperature of certain yeast strains also causes them to produce more acetaldehyde.

- In the first few weeks of fermentation, have you experienced temperature fluctuations? Temperature fluctuations can affect the yeast strain and make it flocculate prematurely.

- What percentage of auxiliary sugar do you use? Any additives exceeding 20% can not provide enough nutrition for yeast strains, so they will produce the more peculiar smell.

- Have you fully aerated the wort? When the oxygen content in the wort is low, the yeast strains cannot fully reproduce during the growth stage and produce peculiar smells.

How does acetaldehyde taste?

How to remove acetaldehyde in finished beer?

How should I avoid acetaldehyde overdose in later brewing?

- Add enough yeast to the beer you are brewing, and use the starter when needed.

- Make sure your yeast is healthy and active before serving.

- Aerate the wort with air or oxygen before fermentation.

- Control the fermentation temperature.

- Let your fermentation complete before bottling or adding clear liquid.

- Once the fermentation has started, do not expose the beer to more oxygen.

- The brewing equipment maintains perfect hygienic habits.

The most common odor in commercial beer and craft beer is the smelly “Light-struck” flavor and aroma. It can make your beer emit a strong smell (it feels like a skunk) and make it unpleasant to drink. Guide to beer off-flavors: Light-struck What is Light-struck? When light hits the beer, the ultraviolet rays interact with

No matter how many times you have brewed beer in the past when you open the first bottle of a new batch, it is always exciting. Maybe the aroma of hops will be as good as expected, maybe the beer will be muddy, or the beer will taste like vinegar. Beer that tastes like vinegar

Beer always contains some form of phenols (phenols and polyphenols, etc.), such as tannins (directly derived from hops and malt). Although low levels of polyphenols can increase the taste of beer, high levels of polyphenols can cause dryness and astringency. When beer glasses are described as phenols, they usually refer to volatile phenols. Volatile phenols

It is not normal for Metallic to appear in any flavored beer. If you can taste Metallic or bloody taste in beer, it is recommended not to drink this beer. Under normal circumstances, the source of iron ions is only a very small amount of iron-containing protein in grains, which will enter the beer during

Some craft beer will produce excessive alcohol taste and aroma. This can vary from a slight alcoholic warmth to strong alcohol that tastes like moonshine. Next, Micet Craft will explore the root cause of the alcoholic odor. In addition, this is also the eighth article about beer’s peculiar smell. If you are interested, you can

The presence of hydrogen sulfide (H2S) in beer will give the beer a unique smell of rotten eggs. In some beer styles, a small amount of hydrogen sulfide will form a unique flavor in the beer. But, if beer contains more hydrogen sulfide, the beer may produce a pungent rotten egg flavor, which is not

One of the most frequently mentioned odors in beer evaluation is dimethyl sulfide (DMS). DMS is a sulfur compound that is generally thought to give beer creamed corn or cooked vegetable characteristics. Most beer brewers know very well how to reduce the risk of DMS entering the beer, such as checking the boiling time and

Is my beer infected? This is a question we often receive. Next, Micet Craft will introduce the content of beer infection. This is also the fourth article in our beer off-flavors series. If you are interested, you can read other articles related to odor. We hope to help you better complete beer brewing. Guide to beer

The most important ester found in beer is isoamyl acetate, which has a flavor like rubber or pear blossom. Isoamyl acetate is considered an ester, or a mixture of alcohol and acid. Because fermentation (yeast converting sugar into alcohol) produces isoamyl acetate, isoamyl acetate is a very common off-flavors in all beer. Although the content

Both commercial brewers and homebrewers are doing their best to reduce the oxygen content in the finished beer. The oxygen in the finished beer will destroy the long-term stability of the beer’s flavor and clarity, as well as cause peculiar smells. The oxidized beer will show a paper peculiar smell or even a sweet stone

The most common odor in commercial beer and craft beer is the smelly “Light-struck” flavor and aroma. It can make your beer emit a strong smell (it feels like a skunk) and make it unpleasant to drink. Guide to beer off-flavors: Light-struck What is Light-struck? When light hits the beer, the ultraviolet rays interact with

No matter how many times you have brewed beer in the past when you open the first bottle of a new batch, it is always exciting. Maybe the aroma of hops will be as good as expected, maybe the beer will be muddy, or the beer will taste like vinegar. Beer that tastes like vinegar

Beer always contains some form of phenols (phenols and polyphenols, etc.), such as tannins (directly derived from hops and malt). Although low levels of polyphenols can increase the taste of beer, high levels of polyphenols can cause dryness and astringency. When beer glasses are described as phenols, they usually refer to volatile phenols. Volatile phenols

It is not normal for Metallic to appear in any flavored beer. If you can taste Metallic or bloody taste in beer, it is recommended not to drink this beer. Under normal circumstances, the source of iron ions is only a very small amount of iron-containing protein in grains, which will enter the beer during

Some craft beer will produce excessive alcohol taste and aroma. This can vary from a slight alcoholic warmth to strong alcohol that tastes like moonshine. Next, Micet Craft will explore the root cause of the alcoholic odor. In addition, this is also the eighth article about beer’s peculiar smell. If you are interested, you can

The presence of hydrogen sulfide (H2S) in beer will give the beer a unique smell of rotten eggs. In some beer styles, a small amount of hydrogen sulfide will form a unique flavor in the beer. But, if beer contains more hydrogen sulfide, the beer may produce a pungent rotten egg flavor, which is not

One of the most frequently mentioned odors in beer evaluation is dimethyl sulfide (DMS). DMS is a sulfur compound that is generally thought to give beer creamed corn or cooked vegetable characteristics. Most beer brewers know very well how to reduce the risk of DMS entering the beer, such as checking the boiling time and

Is my beer infected? This is a question we often receive. Next, Micet Craft will introduce the content of beer infection. This is also the fourth article in our beer off-flavors series. If you are interested, you can read other articles related to odor. We hope to help you better complete beer brewing. Guide to beer

The most important ester found in beer is isoamyl acetate, which has a flavor like rubber or pear blossom. Isoamyl acetate is considered an ester, or a mixture of alcohol and acid. Because fermentation (yeast converting sugar into alcohol) produces isoamyl acetate, isoamyl acetate is a very common off-flavors in all beer. Although the content

Both commercial brewers and homebrewers are doing their best to reduce the oxygen content in the finished beer. The oxygen in the finished beer will destroy the long-term stability of the beer’s flavor and clarity, as well as cause peculiar smells. The oxidized beer will show a paper peculiar smell or even a sweet stone

Fantástico sitio. Un montón de información útil aquí. Se lo envío a algunos amigos y, además, lo comparto delicioso. ¡Y por supuesto, gracias por tu esfuerzo!