With the rise of kombucha in the beverage market, the demand for commercial production is also increasing. Commercial production not only requires efficient brewing speed, but also requires ensuring the hygiene and safety of the production process while maintaining the original flavor. In order to ensure that each batch of kombucha can maintain stable quality and taste, choosing commercial kombucha brewing equipment becomes the key in the production process.

Why choose commercial kombucha brewing equipment?

- Efficient production: Commercial equipment can complete a larger amount of fermentation work in a shorter time, thereby improving production efficiency and meeting market demand.

- Stable quality control: The quality of kombucha is greatly affected by the fermentation process. Commercial equipment can ensure that the fermentation conditions of each batch of products are consistent, thereby achieving quality stability and ensuring the taste experience of consumers.

- Increase production scale: Commercial equipment can usually handle larger volumes of tea liquid and culture medium, which is conducive to expanding production scale and improving the market competitiveness of enterprises.

- Reduce labor costs: Modern commercial kombucha fermentation equipment is usually equipped with an automated control system, which can reduce manual intervention, improve work efficiency, and reduce labor costs.

- Hygiene and safety: Commercial equipment is designed with food safety and hygiene in mind, effectively preventing sources of contamination and ensuring that products meet food safety standards.

Kombucha Brewing Equipment

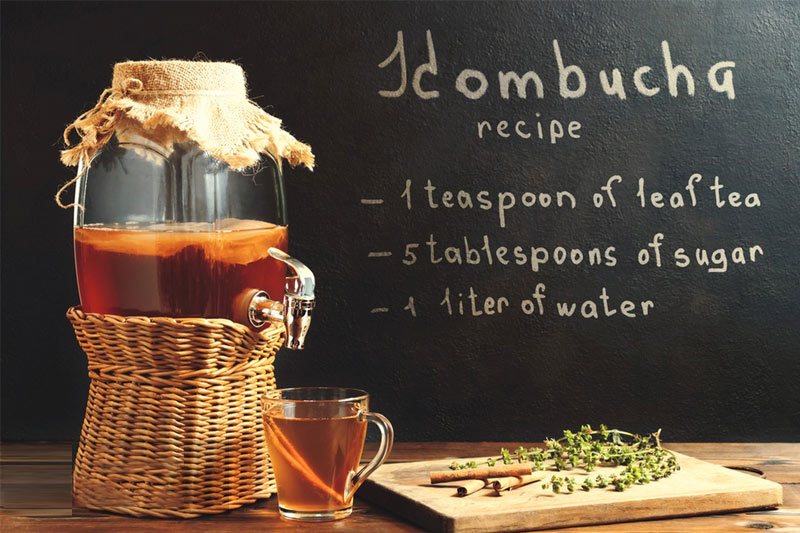

- Brew Container: A basic container for mixing tea, sugar, and water. Usually, materials that are heat-resistant and corrosion-resistant, such as glass or stainless steel, are selected.

- Fermentation Tank: Used to ferment kombucha at a suitable temperature and environment. Fermentation tanks are usually larger sealed containers that can hold tea and SCOBY.

- Filtration System: Used to filter out tea residue and other impurities to ensure that the fermented liquid is clear. Common filters include cloth filters and fine mesh filters.

- Mixing Tank: Used to evenly stir the tea and sugar during the brewing process to ensure that the sugar is completely dissolved and to help bacteria and yeast be evenly distributed. Usually a manual or electric stirrer is used.

- Storage Equipment: After the kombucha has completed the initial fermentation, it may be necessary to ferment it again or store it. Storage equipment is usually glass bottles or food-grade plastic containers that are required to remain sealed and heat-resistant.

- Packaging Equipment: Used to pack the final fermented kombucha into bottles or jars, usually including bottle sealing and labeling equipment.

- Cleaning Equipment: Used to clean all equipment and tools to prevent contamination of the fermentation process. Including brushes, cleaners, and high-pressure water guns.

- SCOBY: In the fermentation process of kombucha, SCOBY is a symbiotic community of bacteria and yeast, which is the key to fermentation and helps tea to be converted into kombucha.

How to choose the right kombucha brewing equipment for commercial use?

Production scale and output requirements

The scale and demand for commercial kombucha production determine the type and size of equipment. Different scales of production require brewing equipment of different capacities. If you are targeting small shops or local markets, you may need some small or medium-sized equipment. If you plan to produce on a large scale and supply the national market, you may need large industrial equipment.

- Output requirements: Estimate the monthly or daily production volume and ensure that the selected equipment can meet the needs.

- Equipment scalability: If the production scale will increase in the future, it is important to choose equipment with scalability. For example, equipment that can add multiple fermentation tanks or expand the raw material processing capacity.

- Space constraints: Choose equipment of the right size according to the space of the store or factory to avoid taking up too much space and affecting the production process.

The degree of automation of the brewing process

Fully automatic equipment: This type of equipment can complete the entire process from tea brewing, sugar addition to fermentation and cooling, reducing human intervention. Suitable for large production lines, saving labor costs, and reducing the risk of human error.

- Semi-automatic equipment: This type of equipment allows merchants to participate in controlling important links, such as temperature control or flavor adjustment during fermentation. Suitable for small and medium-sized production, it can enjoy certain automation advantages while retaining some flexibility.

- Manual equipment: For those merchants with small production scale and more product types, manually operated equipment may be more suitable. Although the production efficiency is lower, the production process and flavor can be adjusted more flexibly.

Material of equipment

Fermentation containers are usually made of stainless steel, glass, plastic, and other materials. For commercial equipment, it is best to choose corrosion-resistant and easy-to-clean stainless steel materials. Such materials can effectively avoid the breeding of bacteria or other contaminants and ensure production hygiene. Stainless steel fermentation containers also have strong high temperature resistance and pressure resistance, which are suitable for most fermentation process needs.

Budget and cost-effectiveness

Although high-end equipment provides more precise control and longer service life, the initial investment is also relatively large. Therefore, when purchasing equipment, merchants need to balance the performance and budget of the equipment. On the premise of ensuring the quality of the equipment, try to choose products with high cost-effectiveness. For small-scale merchants, you can consider gradually expanding the scale of equipment to avoid over-investment.

Convenience in cleaning and maintenance

After long-term use, the equipment will inevitably accumulate bacteria or residues, affecting the fermentation quality. Ideal commercial kombucha brewing equipment should have an easy-to-clean design, such as detachable parts, smooth and seamless surfaces, etc., to reduce bacterial growth and cleaning difficulties. At the same time, the equipment should provide a detailed manual and reliable after-sales service to ensure that problems can be solved promptly.

FAQ

How much space does kombucha fermentation equipment require?

The size of commercial kombucha equipment varies depending on the scale of production. Small equipment usually requires less space, while large equipment requires a more spacious production area.

What materials are kombucha brewing equipment made of? Which material is best?

The main materials are stainless steel, such as 304 or 316 grade stainless steel, food-grade plastic and glass. Stainless steel is the most common because it is corrosion-resistant, easy to clean and meets food safety standards.

How can commercial kombucha brewing equipment reduce production costs?

- Through automated control, reduce labor costs and improve production efficiency.

- An efficient heat energy utilization system can reduce energy consumption.

- Optimize equipment design to reduce raw material waste and improve raw material utilization.

- Maintain equipment regularly to extend service life and avoid frequent repairs or replacement of parts.

- Choose equipment with the right capacity to avoid production waste caused by being too large or too small.

Can commercial kombucha equipment be used for batch production?

Yes, modern commercial kombucha equipment is usually designed to produce multiple batches at the same time and even blend flavors. Producers can adjust the raw material ratio according to demand to produce kombucha with different flavors.

How to extend the service life of kombucha fermentation equipment?

- Regular cleaning: Clean the equipment in time after use to avoid accumulation of fermentation residues and prevent bacterial growth.

- Avoid high temperature environment: Place the equipment in a cool and dry place, avoid direct sunlight and high temperature environment to extend the service life of the equipment.

- Use high-quality raw materials: Ensure the use of raw materials that meet the requirements to avoid equipment damage or poor fermentation due to unqualified materials.

- Timely maintenance: Regularly check various parts of the equipment, such as motors, transmission systems, etc., and promptly detect and replace worn parts.