- Change and maintain consistent pasteurization temperature.

- Transfer heat without contaminating the heating fluid.

- Energy saving is achieved by reusing the heating fluid to heat the fluid in a repeatable cycle.

- Heated water and cleaning fluids for efficient clean-in-place (CIP) systems.

- Accurate temperature control is achieved during the sterilization stage.

Lower pressure drop

Heat exchange efficiency

- A higher heat transfer coefficient can be obtained due to corrugated plate and higher speed.

- Allows more heat transfer due to pure countercurrent flow and close temperature.

- Higher energy recovery can be achieved due to these closer temperature methods.

| Overall Heat Transfer Coefficient - U - | ||

|---|---|---|

| Liquid-to-Liquid Heat Transfer | Heat Transfer Coefficient W/(m2 K) | Btu/(ft2 °F h) |

| Shell and Tube | 150-1200 | 25-200 |

| Plate and Frame | 1000-4000 | 150-700 |

Reduce maintenance

Smaller footprint

Scalability

Capital expenditure

Plate Type

- For viscous products, plate heat exchangers require the correct choice of plate type.

- For products with particles, plate heat exchangers require special plates with ground contact points and/or wider gaps.

| Average Gap | Particle Size | Fiber Length | Pulp (%) | Viscosity CPS | |

|---|---|---|---|---|---|

| Typical Industrial Plate | 2.4-3.95mm | Dia 0.5mm | 1mm | 2 | 2500 |

| Typical Sanitary Plate | 3.95mm | Dia 0.5mm | 1mm | 3 | 5000 |

| Low Contact Point Plate | Up to 8mm | Dia 0.5mm | 5mm | 7 | 1000 |

- Milk and dairy pasteurization

- Ultra-high temperature sterilization

- Beverage and energy drink pasteurization

- Standard and pulpy juice pasteurization

- Beer wort and beer pasteurization and cooling

- Liquid egg processing

- Bottled water treatment

- Soups, sauces, and starch heating

- Ketchup and mustard heating and cooling

Frequently Asked Questions

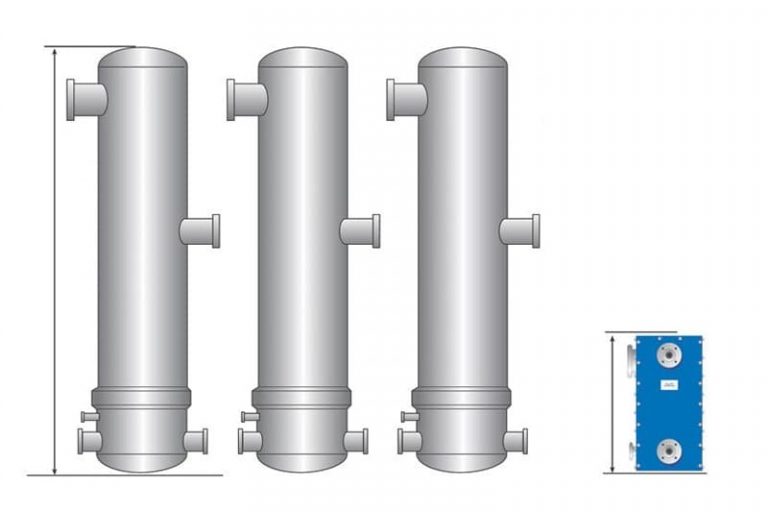

What are the advantages and disadvantages of plate heat exchangers and shell and tube heat exchangers?

If you’ve ever looked into liquid cooling products, you’ve probably come across two options, shell, and tube or plate heat exchangers. Shell-and-tube and plate heat exchangers work on the same principle, exchanging heat between the two fluids by heat conduction, but they are constructed very differently. If you don’t understand the benefits of both designs, it can be difficult to decide which one is best for you. Let’s take a look at their respective advantages.

Advantages of shell and tube heat exchangers

- Smaller designs can reduce costs.

- Service just got easier.

- O-rings make them inexpensive to repair.

- A better solution for seawater coolant or other fluids that risk clogging tight spaces.

- Better mounting options (tee, union configuration, etc.) are available.

- The ideal solution for hydraulic power units, mining machinery, seawater cooling vessels, and swimming pool heating.

Disadvantages of shell and tube heat exchangers

- Takes up a lot of space.

- Difficult to clean and maintain.

Advantages of plate heat exchangers

- With a more compact design, less space is required.

- Low-cost option where stainless steel is required.

- Higher work pressure and ability.

- Higher temperature capability.

- Ideal for small district heating, beverage cooling, food and pharmaceutical production, and low load oil cooling applications.

Disadvantages of plate heat exchangers

- Relatively low operating temperature.

- Additional maintenance costs due to gaskets.

- Not suitable for products with very high viscosity or very large particles.

- The energy transfer effect of two fluids with a large temperature difference in a plate heat Exchanger is not as good as that in a shell and tube heat exchanger.

- Greater risk of leakage.

What is the difference between a plate heat exchanger and a shell and tube heat exchanger?

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive