How does the brewing water affect the taste of beer?

- The hardness and mineral composition of the water will give the beer a unique flavor and affect the fermentation process.

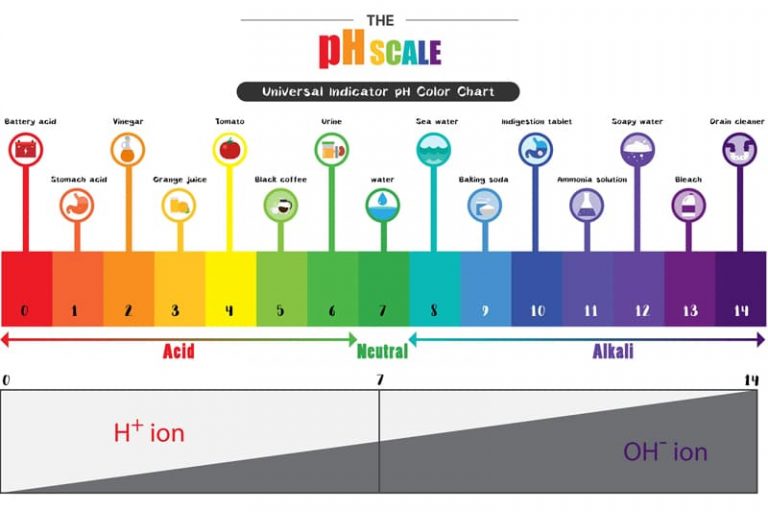

- The pH value promotes the enzymatic effect in the mash and promotes the growth of yeast during the fermentation stage.

- Alkalinity creates a buffer to protect the pH during the entire brewing process from fluctuations, to ensure that bacteria cannot grow, and to remove excess tannins from the beer.

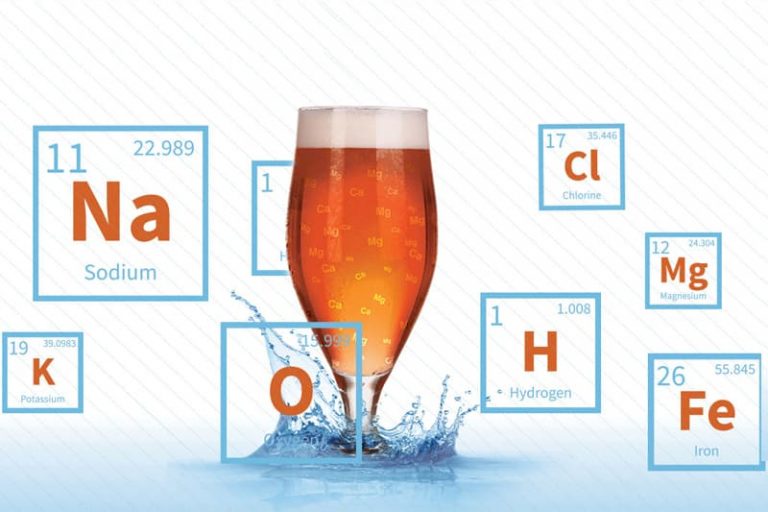

How do minerals in the water affect the taste of beer?

Beneficial ions in brewing water

Calcium (Ca+2)

- Plaster

- Calcium sulfate

- Calcium chloride

- Slaked lime

Magnesium (Mg+2)

- Epsom salt (magnesium sulfate)

Sodium (Na+1)

- No iodized salt or sea salt

- Baking soda (sodium bicarbonate)

Chloride (Cl-)

- Calcium chloride

- Sodium chloride

Sulfate (SO4-2)

- Calcium sulfate

- Plaster

- Epsom salt (magnesium sulfate)

Carbonate and bicarbonate (CO3-2/HCO3)

- Baking soda (calcium bicarbonate)

- Chalk

Ions that will destroy the brewing water

Chlorine and chloramine (Cl2)

Iron (Fe+2 & Fe+3)

Manganese (Mn+2)

Nitrate/Nitrite (NO3- & NO2-2)

How does pH affect beer brewing?

- Lactic acid: Lactic acid is an organic by-product of milk fermentation and is usually used to lower the pH of the mash. Lactic acid will not add an unpleasant taste to the mash and will significantly reduce the pH.

- Phosphoric acid: Phosphoric acid is an inorganic acid found in many commercial beverage products. Its advantage is that it does not give beer any taste. Phosphoric acid is less acidic than lactic acid, so it is a more forgiving product when trying to adjust pH.

- Buffers and stabilizers: They react with the phosphate in the malt to reach the target pH. However, using them will increase the content of calcium and magnesium in beer.

What is the best water for brewing beer?

Types of water filters in breweries

- Particle filter: The particle filter uses a filter element or sheet to capture larger particles in the water while allowing smaller liquids to flow through. This type of filtration can remove solids, sediments, dirt, and other larger particles from the water.

- Carbon filter: A carbon filter is usually used in combination with a particulate filter. Carbon filters can be used to remove chlorine and other impurities in the water. This type of filtration is essential for craft beer brewing. Most municipal water supply systems use chlorine to disinfect water. If chlorine remains in the brewing water, it will react with malt and hops to produce chlorophenols and cause the beer to have a plastic-like taste. These resulting chlorophenols can be detected in very small amounts, so when using city water for brewing, filtration methods must be used to remove this chlorine precursor.

- Granular activated carbon (GAC) filter: This type of filter is very suitable for removing odors, pesticides, chlorine, chloramines, and other similar impurities in brewing water.

- Reverse osmosis filtration system: Reverse osmosis (RO) filtration is generally considered to be the most effective filtration method, but it is also very expensive. RO uses a porous membrane to remove molecules, ions, and larger particles in water, and only allows water molecules to pass through.

Clean filter for craft beer brewing

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive