The journey of beer making has always fascinated me. After 15 years in the brewing industry, I’ve seen many brewers struggle with understanding the basic process, leading to inconsistent results and wasted resources.

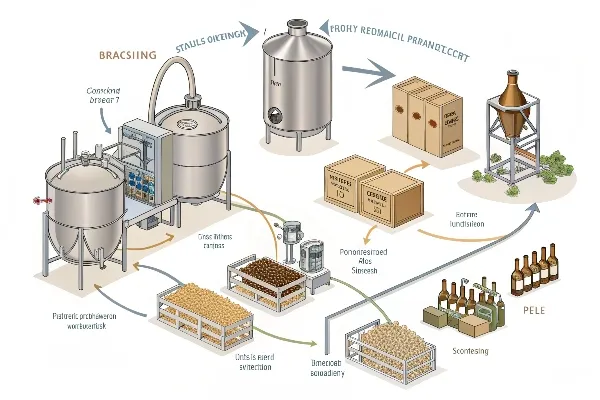

The beer brewing process consists of seven essential steps: milling, mashing, lautering, boiling, cooling, fermentation, and packaging. Each step requires precise control of temperature, time, and ingredients to create the perfect brew.

Let me take you through each step in detail, sharing insights I’ve gained from helping set up over 1000 breweries worldwide. This guide will help you understand the complete brewing journey.

How to Make Beer in a Factory?

I remember my first day overseeing a large-scale brewing operation. The sheer size of industrial equipment can be overwhelming, but the basic principles remain the same as home brewing.

Modern brewery factories follow a systematic approach using specialized equipment for each brewing step. The process starts with grain handling systems and ends with automated packaging lines.

Key Equipment Requirements

- Grain Mill System

- Capacity: 2-5 tons/hour

- Type: 6-roller mill

- Power: 15-30 kW

Process Control Systems

- Mashing Control

- Temperature range: 45-78°C

- Time monitoring

- pH control

Quality Control Points

| Stage | Parameters | Acceptable Range |

|---|---|---|

| Mashing | Temperature | 62-72°C |

| Boiling | Time | 60-90 minutes |

| Fermentation | Temperature | 10-25°C |

The factory brewing process requires strict adherence to standard operating procedures. From my experience working with numerous breweries, I’ve found that automated control systems are essential for consistency. Modern brewing facilities use PLC systems to monitor and adjust parameters in real-time.

What is an Ale vs Lager?

During my visits to different breweries worldwide, I noticed many people confuse these two fundamental beer types. The difference lies mainly in the fermentation process.

Ales and lagers differ primarily in their yeast strains and fermentation temperatures. Ales use top-fermenting yeast at warmer temperatures (15-25°C), while lagers use bottom-fermenting yeast at cooler temperatures (7-13°C).

Characteristics Comparison

| Feature | Ale | Lager |

|---|---|---|

| Fermentation Temperature | 15-25°C | 7-13°C |

| Fermentation Time | 2-3 weeks | 4-6 weeks |

| Yeast Type | Top-fermenting | Bottom-fermenting |

| Flavor Profile | Fruity, complex | Clean, crisp |

In my experience managing both ale and lager production lines, I’ve observed that lagers require more precise temperature control and longer conditioning times. The equipment setup must account for these differences to achieve optimal results.

What Liquid is Used in Brewing?

Water quality was one of my main concerns when I first started designing brewery systems. It’s surprising how many brewers overlook this crucial component.

Water is the primary liquid used in brewing, making up 90-95% of beer. The mineral content and pH level of brewing water significantly impact the final product’s taste and quality.

Water Requirements

- Main Water Parameters

- pH: 5.2-5.6

- Calcium: 50-150 ppm

- Alkalinity: 0-50 ppm

Treatment Methods

| Method | Purpose | Equipment Needed |

|---|---|---|

| Reverse Osmosis | Remove impurities | RO system |

| Carbon Filtration | Remove chlorine | Carbon filters |

| UV Treatment | Sanitization | UV light system |

Based on my experience setting up water treatment systems in various breweries, I recommend investing in a comprehensive water analysis and treatment system. This ensures consistent water quality throughout the brewing process.

How Much Malt for 5 Gallons of Beer?

This is a question I frequently encounter when helping craft brewers scale their recipes. The amount varies depending on the beer style and desired alcohol content.

For a standard 5-gallon batch of beer with 5% ABV, you typically need 8-12 pounds of base malt. The exact amount depends on the malt’s potential extract value and the target original gravity.

Malt Calculator

| Beer Style | Base Malt (lbs) | Specialty Malt (lbs) |

|---|---|---|

| Light Lager | 8-9 | 0-0.5 |

| Pale Ale | 10-11 | 1-2 |

| Stout | 11-12 | 2-3 |

The efficiency of your mashing process affects the amount of malt needed. In professional brewing, we typically achieve 75-85% efficiency. I always recommend starting with standard recipes and adjusting based on your system’s performance.

Conclusion

Understanding these fundamental aspects of brewing is crucial for success. From water quality to malt quantities, each element plays a vital role in creating exceptional beer. Remember to maintain precise control over each step for consistent results.