After helping countless brewers transition to all-grain brewing, I’ve developed a clear understanding of what equipment truly matters for success.

Starting all-grain brewing requires essential equipment including a mash tun, brew kettle, wort chiller, fermentation vessel, and temperature control system. Quality ingredients and proper sanitization tools are also crucial.

Let me share my practical experience about the equipment and process that will ensure your success in all-grain brewing.

How Much Grain Do I Need For A 5 Gallon Beer Batch?

As someone who regularly helps brewers calculate their grain bills, I know this question is crucial for consistent results.

A typical 5-gallon batch requires 8-12 pounds of base grain, depending on your target gravity. Additional specialty grains usually make up 5-15% of the total grain bill.

Grain Calculator Guide

Base Grain Requirements

| Beer Style | Base Grain Amount | Target OG |

|---|---|---|

| Light Ale | 8-9 lbs | 1.040-1.045 |

| Pale Ale | 10-11 lbs | 1.050-1.055 |

| IPA | 11-13 lbs | 1.060-1.065 |

| Imperial Stout | 14-16 lbs | 1.080-1.090 |

Specialty Grain Additions

- Color Grains

- Crystal malt: 0.5-1.5 lbs

- Roasted barley: 0.25-0.75 lbs

- Chocolate malt: 0.25-0.5 lbs

- Body-Building Grains

- Wheat malt: 0.5-2 lbs

- Oats: 0.5-1 lb

- Munich malt: 1-2 lbs

From my brewing experience, I’ve found that accurate grain measurements and proper milling are crucial for achieving consistent results.

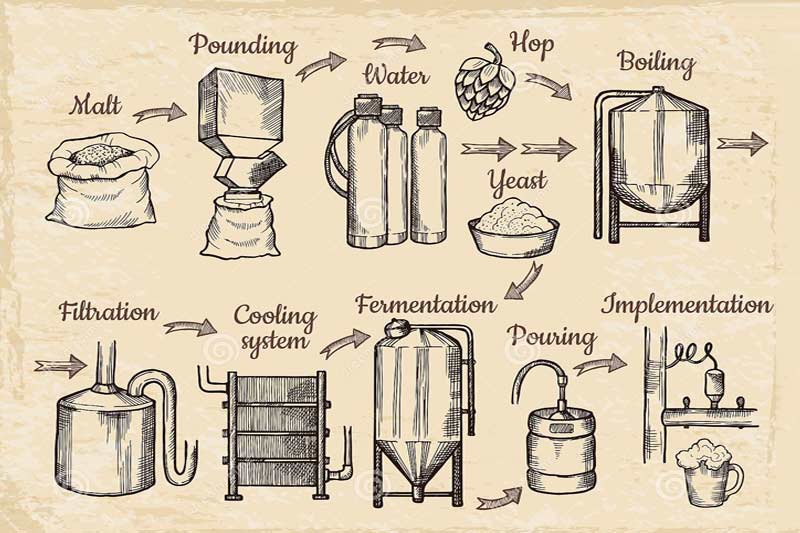

What Is The Correct Order Of Brewing?

Through years of training new brewers, I’ve developed a clear understanding of the optimal brewing sequence.

The correct brewing order starts with mashing, followed by lautering, boiling, cooling, fermentation, and finally conditioning. Each step must be executed in sequence for successful beer production.

Detailed Brewing Sequence

Pre-Brew Preparation

| Stage | Duration | Key Points |

|---|---|---|

| Water Treatment | 30 mins | pH adjustment |

| Grain Milling | 15-30 mins | Proper crush size |

| Equipment Sanitizing | 30 mins | Complete coverage |

| Temperature Calibration | 15 mins | Accurate readings |

Main Brewing Steps

- Mashing Process

- Strike water heating

- Grain incorporation

- Temperature maintenance

- Enzyme conversion

- Lautering

- Vorlauf (recirculation)

- First runnings

- Sparging

- Final runoff

I’ve found that following this sequence consistently leads to better quality beer and fewer problems during brewing.

What Are The Four Fundamentals Of Brewing?

Based on my experience training brewers worldwide, these fundamentals are essential for quality beer production.

The four fundamentals of brewing are proper sanitization, temperature control, time management, and ingredient quality. These elements form the foundation of successful brewing.

Understanding Brewing Fundamentals

1. Sanitization Standards

- Equipment cleaning protocols

- Sanitizer types and uses

- Contact time requirements

- Quality verification methods

2. Temperature Control

| Process Stage | Ideal Temperature | Tolerance |

|---|---|---|

| Mashing | 148-158°F | ±2°F |

| Boiling | 212°F | N/A |

| Fermentation | 65-70°F | ±3°F |

| Conditioning | 33-40°F | ±2°F |

3. Time Management

- Mash duration tracking

- Boil time monitoring

- Fermentation scheduling

- Conditioning periods

4. Ingredient Quality

- Grain freshness

- Hop storage

- Yeast viability

- Water chemistry

What Are The 7 Steps Of The Beer Brewing Process?

Drawing from my extensive brewing experience, I’ll outline the seven critical steps every brewer must master.

The seven steps of brewing are malting, mashing, lautering, boiling, cooling, fermenting, and conditioning. Each step requires specific equipment and careful attention to detail.

Detailed Brewing Steps

1. Malting

- Grain selection

- Moisture content

- Germination control

- Kilning process

2. Mashing

| Sub-Step | Temperature | Duration |

|---|---|---|

| Dough-In | 95-105°F | 5-10 mins |

| Protein Rest | 120-130°F | 15-30 mins |

| Saccharification | 148-158°F | 60 mins |

| Mash-Out | 168-170°F | 10 mins |

3. Lautering

- Bed setting

- Vorlauf process

- Sparging technique

- Runoff rate

4. Boiling

- Hop additions

- Kettle reactions

- Evaporation rate

- Clarity development

5. Cooling

- Heat exchanger operation

- Temperature targets

- Oxygen introduction

- Sanitation maintenance

6. Fermenting

- Yeast pitching

- Temperature control

- Pressure monitoring

- Gravity tracking

7. Conditioning

- Temperature reduction

- Clarity improvement

- Flavor development

- Carbonation control

Conclusion

Starting all-grain brewing requires proper equipment, understanding of the process steps, and attention to fundamental brewing principles. Success comes from maintaining consistency in each aspect of the brewing process.