To open a brewery is an exhilarating business idea that calls for thorough planning and a huge capital investment in the necessary machinery. Each phase of brewing necessitates specific tools and equipment to ensure efficiency and quality, ranging from packaging solutions to brewhouse. This article will provide all necessary details on how to build a commercial brewery which starts from the first expenses up to the operational costs.

Key Takeaways

- Setting up a brewhouse entails multiple components such as lauter tun, mashtun, brew kettle and whirlpool.

- Fermentation equipment includes tanks, cooling systems, and monitoring tools for fermentation control.

- There are filters, storage tanks, refrigeration units for filtration and storage of beer.

- The final product should be packaged using bottling or canning or kegs.

- Although cost is essential at start-up level; it is also about long run maintenance and future scaling.

Setting Up the Brewhouse

The heart of a brewery is the brewhouse, where the initial steps of brewing take place. It typically contains a number of constituent parts, each one with its own function in the brewing process. A well-designed brewhouse guarantees efficiency and quality in beer production.

Fermentation Equipment

1、Fermentation Tanks

For beer fermentation, fermentation tanks are essential because they create an environment fit for life activities and metabolism of microorganisms. These come in various sizes and designs to suit different brewery capacities such as cider, wine, beer and kombucha fermenters.

2、Cooling Systems

Cooling systems are very important in maintaining optimal temperature during fermentation. Such systems include glycol cooling systems and cellar controls that keep yeast active and healthy while the process goes on.

3、Fermentation Monitoring Tools

Monitoring tools play a crucial role by keeping track of how fermentation is progressing. Their assistance is indispensable when it comes to measuring temperature levels, pH values as well as gravities thus making sure that fermentation is going smoothly as planned. Proper monitoring helps avoid potential problems and leads to constant final products.

To make the best beers that have smaller carbon footprints; investing in high-quality fermentation equipment cannot be overemphasized.

Filtration and Storage

1、Filters

The brewing filtration stage is quite essential as it helps in the extraction of solids such as live yeasts from the liquid before filling. Live yeast is edible, but it can be affected by temperature variations which may change beer’s taste. Due to this, yeast should be stored in areas where temperature can be easily controlled. Filtration technology that removes yeast and debris can control the taste of beer.

There are many kinds of filtering equipment available on the market today. Among them are plate filters and candle filters, which are more popular.

Plate Filters: They are cost friendly options for filtration process. Made up of vertical cloth-coated plates with hollow frames at a 90 degree angle, a plate filter has got beer put into its frame, which lets solids get trapped by its cloth as liquid goes into tubes that is free from any yeast.

Candle Filters: Larger breweries mostly use these ones. A candle filter consists of hollow circular tubes with small openings inside cylindrical shape container where beer-diatomaceous earth mixture will be put so that the filter traps solids thereby purifying it.

The choice of filtration equipment depends on how big your plant is and amount you want to spend on buying one; both these filtration devices serve well in solving this problem.

2、Storage Tanks

After the fermentation period involving yeast ends, the beer is filtered and pumped into another tank called Brite tanks. The term brite tank signifies beer maturing further through clarification and carbonation processes. Once settled and matured, this kind of beer is ready for bottling or kegging or even canning while direct service from this vessel can also take place.

3、Refrigeration Units

For quality purposes and giving great taste refrigeration units come handy by maintaining freshness of beers for longer time periods. With these units beer gets stored at optimal temperatures thus avoiding any unwanted flavor changes occurring on it. Proper refrigeration matters both within brewery settings over short term and long term preservation that occurs during distribution.

The quality of the final product is maintained using refrigeration units among other industrial brewing & wine making equipment.

Packaging Solutions

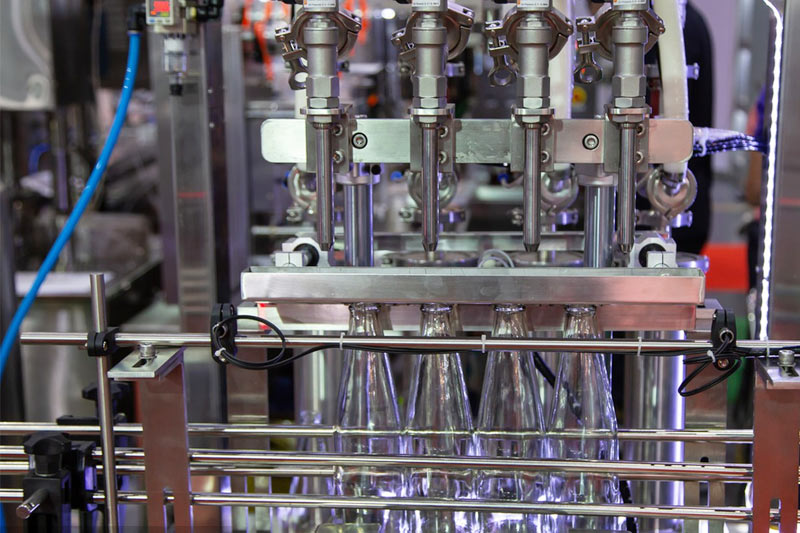

1、Bottling Equipment

Bottling gears are a must have for your beer to reach your customers. A filling machine is all you need whether you choose cans or bottles. This is because there are different types of these machines that one can select from especially in the event of bottling machine, it’s good to know whether one will package carbonated beers or rely on bottle conditioned beers to carbonate. If this is what you plan, then go buy an Isobaric (counter pressure) bottling/ canning line.

2、Canning Equipment

A canning system helps get the beer into distributors and customers. It consists of containers like cannisters, cannister tops as well as tags. All stamps should comply with the rules set for marketing and distribution alcoholic drinks. Ensure that your production needs fit within the capacity of the provided packaging system.

3、Kegs

One more popular way to package beers for instance in bars and restaurants is kegs kegs. To use kegs as a means of packaging, you need a keg filling machine may be supplemented with a keg washer. Kegs assist in maintaining flavor and cleanness during transit.

Zumbiel’s lightning-fast custom beer packaging will unlock your brand’s potential. We have served many startups, national brands, and regional craft brewers in America.

Essential Utilities and Maintenance

Setting up a brewery involves more than brewing equipment. Important utilities and maintenance are important to ensure that your brewery runs smoothly and lasts long. The following are the key components you need to consider:

1、Piping Systems

An efficient liquid transportation within the brewery is fully dependent on a well-designed piping system. These include water, wort, and beer. Make sure that the materials used are of food-grade quality and can withstand high temperature and pressure.

2、Cleaning Tools

In brewing, cleanliness is next to godliness. Essential cleaning tools include:

Hand Mitts

Bibbed Gowns

First Aid Box

Date Stickers

Sani-buckets

Bar towels

Food safe sanitizers

Safety Data Sheets for Chemicals

A separate cleaning station can help simplify the cleaning process as well as make certain that all equipment is sanitized properly.

3、Refrigeration

Raw materials and finished products require refrigeration units at correct temperatures thus walk-in coolers as well as smaller refrigeration units for ingredients exist too. Good refrigeration assists in maintaining beer quality while keeping it fresh for longer periods.

Regular maintenance of these utilities helps prevent unexpected failures and ensures your machines last longer.

Cost Considerations

1、Initial Investment

At the moment a brewery is beginning, the initial investment can be very expensive. In order to understand and control brewery startup expenses, it’s necessary to develop a detailed budget and accurate financial forecasts. Estimate the cost of equipment, construction and permits. Always be wary of equipment that is priced much lower than other options thus it may be low quality and require regular maintenance.

2、Maintenance Costs

Maintenance costs are not one-off expenses. For instance, high-quality equipment comes at a higher initial price but this may save you money in future by minimizing the need for frequent repairs. Have some working capital for such continuous expenditures even before starting your revenue generation phase.

3、Scaling Up

You might have to scale up if your brewery turns out a huge success. This could turn out to be costly and complicated; particularly if your initial equipment has limited capacity. When making your first investment consider growth potential so as to avoid costly ammendments later on.

“If you know your homework well enough with all its details and think you will pay more for this project then I would strongly advise you add 50% extra because of unplanned happenings, and see if under those circumstances business plan will still make sense.”

| Cost Component | Estimated Cost Range |

| Equipment | $100,000 – $500,000 |

| Construction | $200,000 – $1,000,000 |

| Permits | $10,000 – $50,000 |

| Maintenance | $5,000 – $20,000/year |

Conclusion

It can be quite an exciting venture to start a brewery because this requires careful planning and investing in suitable machinery. In the brewing process every single equipment such as kettles, boilers, fermentation tanks, cooling systems plays a very vital role. By understanding the important parts that are the brewhouse, storage tanks and bottling or canning equipment, you are able to lay a solid foundation for your brewery. Remember good equipment equals good brew so choose wisely. With right tools and passion for beer making your dream of owning a brewery can become a reality.

FAQ

- What kind of equipment is needed to build a brewery?

To start construction of a brewery it is necessary to have kettles, boilers, fermentation tanks, filters , cooling systems , storage tanks , kegs , bottling or canning equipment , refrigeration units , piping networks , cleaning tools .

- What do you understand by the term brewhouse?

This is all about vessels where initial brewing takes place in any craft brewery; these range from mash mixer to whirpool.

- What are the essential pieces of equipment for the fermentation process?

For the purpose of fermentation process itself there should be tanks for fermenting mixed with cooling systems and appropriate monitoring tools.

- What types of packaging solutions are available for breweries?

Breweries can use bottling equipment, canning equipment, and kegs for packaging their products.

- What are the key considerations for brewery costs?

Among the significant costs that a brewery owner needs to consider include initial capital outlay, maintenance and scaling up costs.

- Why is refrigeration important in a brewery?

Refrigeration is an essential requirement in terms of ingredients’ storage, fermentation temperature control as well as keeping final product fresh.