As a brewery equipment manufacturer with 15 years of experience, I’ve seen many brewers struggle with choosing the right equipment. The wrong choice can lead to inconsistent beer quality and wasted resources.

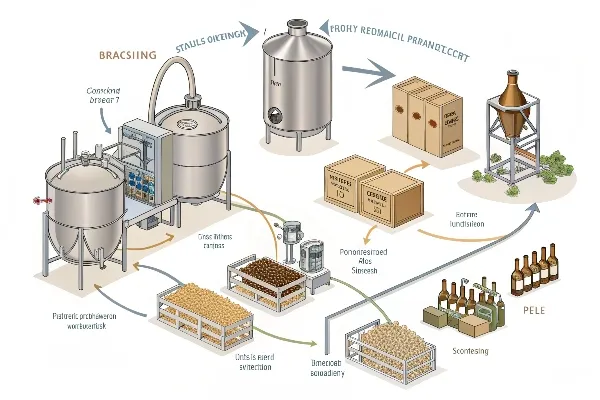

The essential equipment for beer brewing includes mashing systems, fermentation tanks, cooling systems, and bottling lines. For a basic commercial brewery setup, you’ll need at least $50,000 worth of equipment to start producing quality beer consistently.

Let me share my expertise from helping set up over 1000 breweries worldwide. I’ll guide you through everything you need to know about brewing equipment.

What Are the Three Types of Brewing Equipment?

I’ve noticed many new brewers get overwhelmed by the variety of brewing equipment available. It’s crucial to understand the basic categories before making any investment decisions.

The three main types of brewing equipment are hot-side equipment (mashing and boiling), cold-side equipment (fermentation and conditioning), and packaging equipment (bottling and kegging).

Detailed Breakdown of Brewing Equipment Types

Hot-Side Equipment

- Mash Tun

- Purpose: Converts grain starches into fermentable sugars

- Capacity: Usually 1.2x final batch size

- Material: Stainless steel 304/316

- Brew Kettle

- Function: Boiling and hop addition

- Features: Steam jacket heating

- Control: Digital temperature monitoring

Cold-Side Equipment

- Fermentation Tanks

- Type: Cylindroconical

- Temperature Control: Glycol cooling

- Pressure Rating: 2-3 bar

- Bright Tanks

- Purpose: Beer conditioning

- Features: Carbonation capability

- Design: Pressure-rated vessels

Packaging Equipment

- Filling Systems

- Types: Counter-pressure fillers

- Speed: 500-2000 bottles/hour

- Controls: Automated filling level

- Labeling Machines

- Accuracy: ±1mm

- Speed: Matches filling line

- Features: Date coding capability

What Are the 5 Steps of the Beer Brewing Process?

In my years of designing brewery systems, I’ve learned that understanding the brewing process is crucial for selecting the right equipment. Each step requires specific tools and conditions.

The five main steps are milling, mashing, boiling, fermentation, and packaging. Each step needs specialized equipment to ensure consistent quality.

Step-by-Step Equipment Requirements

1. Milling

- Grain Mill

- Capacity: 100-500 kg/hour

- Roller Gap: 0.039-0.045 inches

- Motor Power: 2-5 HP

- Storage Bins

- Material: Food-grade plastic

- Size: Based on batch requirements

- Features: Moisture-proof sealing

2. Mashing

- Mash Tun Specifications

- Temperature Range: 145-170°F

- Agitator Speed: 20-40 RPM

- Heat Source: Steam/Electric

- Process Controls

- PID Controllers

- Temperature Probes

- Flow Meters

3. Boiling

- Kettle Features

- Heating Method: Direct/Indirect

- Evaporation Rate: 8-10%

- Whirlpool Integration

- Hop Addition Systems

- Automated dosing

- Hop backs

- Filtration screens

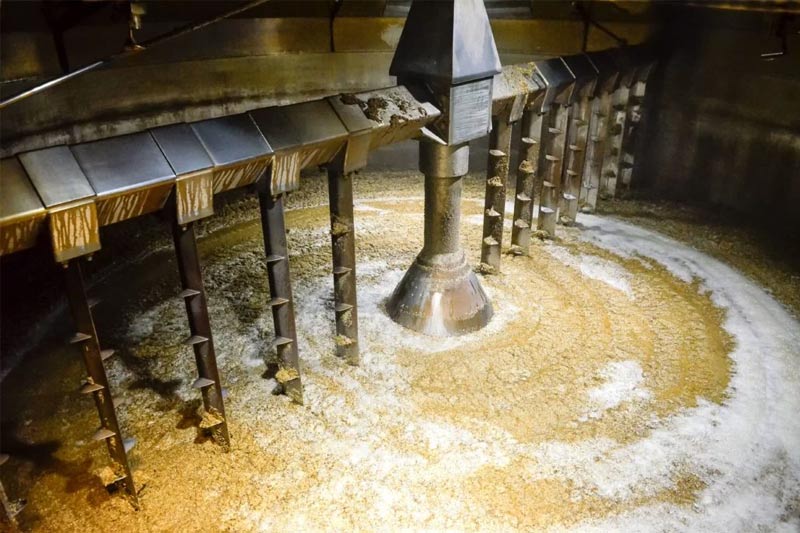

4. Fermentation

- Tank Design

- Cooling Zones

- CIP Capability

- Pressure Rating

- Monitoring Systems

- Temperature Control

- Pressure Gauges

- Sampling Ports

5. Packaging

- Equipment Types

- Bottle Fillers

- Keg Washers

- Can Seamers

- Quality Control

- DO Meters

- CO2 Meters

- Fill Level Checks

How Hard Is It to Make Beer?

From my experience working with hundreds of breweries, I can tell you that brewing beer isn’t necessarily hard, but it requires attention to detail and the right equipment setup.

The complexity depends on your scale and quality goals. Small-batch brewing is relatively simple, but commercial brewing requires precise control and professional equipment.

Key Factors Affecting Brewing Difficulty

Equipment Complexity

- Basic Setup

- Manual controls

- Simple vessels

- Basic monitoring

- Advanced Systems

- PLC automation

- Multiple vessels

- Digital monitoring

Process Control

- Temperature Management

- Mashing accuracy

- Fermentation control

- Cooling efficiency

- Time Management

- Process scheduling

- Fermentation duration

- Packaging timing

Quality Assurance

- Testing Equipment

- pH meters

- Hydrometers

- Thermometers

- Documentation

- Batch records

- Quality checks

- Maintenance logs

What Are the Four Fundamentals of Brewing?

Based on my decades of experience in the brewing industry, I’ve identified that success in brewing comes down to four fundamental elements that every brewer must master.

The four fundamentals are ingredients, equipment, process control, and sanitation. Getting these right is essential for producing high-quality beer consistently.

Analysis of Brewing Fundamentals

1. Ingredients

- Quality Control

- Grain analysis

- Hop storage

- Water treatment

- Storage Systems

- Temperature control

- Humidity monitoring

- Inventory tracking

2. Equipment

- Maintenance

- Regular cleaning

- Calibration

- Replacement parts

- Operation

- Staff training

- Standard procedures

- Safety protocols

3. Process Control

- Documentation

- Recipe management

- Batch tracking

- Quality records

- Monitoring

- Temperature logs

- Pressure readings

- Time tracking

4. Sanitation

- Cleaning Systems

- CIP equipment

- Chemical storage

- Water treatment

- Verification

- ATP testing

- Visual inspection

- Microbial analysis

Conclusion

Successful brewing requires the right equipment, proper understanding of the process, and attention to fundamentals. With proper planning and investment in quality equipment, any brewery can produce excellent beer consistently.