In the process of beer brewing, the wort cooler is a crucial piece of equipment, which is directly related to the quality and production efficiency of the final beer. The main function of the wort cooler is to quickly cool the boiled wort to the fermentation temperature required by the yeast, prevent excessive temperature from damaging the yeast activity, and avoid the negative impact of oxidation on the flavor of the beer. Although it is a seemingly simple device in beer brewing, it plays an indispensable role in the entire brewing process.

What is a wort cooler?

The wort cooler is a device used in beer brewing to quickly cool the boiled wort to the temperature required for fermentation. After the boiling process is over, the temperature of the wort is usually very high, usually reaching more than 100°C. If it is not cooled in time, the yeast in the wort may die or lose its activity due to the high temperature, affecting the fermentation process, and ultimately affecting the taste, alcohol content, and quality of the beer. In addition, high-temperature wort is also prone to oxidation reactions, causing the deterioration of the flavor of the beer. Therefore, it is very critical to quickly and effectively cool the wort to a temperature suitable for yeast fermentation (generally 18°C to 24°C).

Why Chill Wort?

After boiling, the wort needs to be cooled for a variety of reasons. The wort needs to be cool enough so that the yeast can survive and brew well. Most beer yeasts work best between 68–72° F (20–22° C); most lager yeasts work best at 45–57° F (7–14° C). Also, to prevent shock from rapid temperature changes, the temperature difference between the yeast culture and the wort at pitching should be less than 10° F (-12° C).

Besides yeast health, there are other reasons for wort cooling. Cooling wort causes solids, called a cold break, to form and come out of the solution. This break is left behind when the wort is transferred from the kettle to the fermenter.

Chilling wort also slows the production of dimethyl sulfide (DMS). DMS is a volatile substance produced in some words, primarily those made from lager malt. DMS smells like cooked corn and is generally considered a beer defect, although it is noticeable and intentional in some commercial beers.

Cooling the wort quickly can also slow the growth of some wort contaminants. Once the wort temperature drops to around 160° F (71° C), several bacteria (called wort breakers) can quickly grow and create off-flavors in the wort. Quickly moving work to fermentation temperature and adding yeast can minimize the impact of these bacteria on the beer.

Working principle of a wort cooler

The core function of a wort cooler is to quickly transfer the high-temperature heat of the wort to a cooling medium (such as cold water or ice water) through the principle of heat exchange, to achieve the cooling of the wort. This process is usually completed in the following ways:

- Heat exchange: In the cooler, wort is in contact with a cooling liquid (such as cold water or refrigeration liquid) through one or more heat transfer surfaces. Heat is transferred from the high-temperature wort to the cooling liquid, causing the wort temperature to drop rapidly. The higher the heat exchange efficiency, the faster the cooling speed.

- Cooling speed: In order to avoid excessive oxidation reaction and taste loss of wort during the cooling process, it is usually necessary to cool down as quickly as possible. Rapid cooling can not only maintain the flavor of wort, but also reduce the growth of any bacteria or microorganisms, and improve the success rate of yeast fermentation.

- Cooling method: According to different designs, wort coolers can use different cooling media and methods, including water cooling, air cooling, and mechanical refrigeration through refrigerators.

Types of Wort Coolers

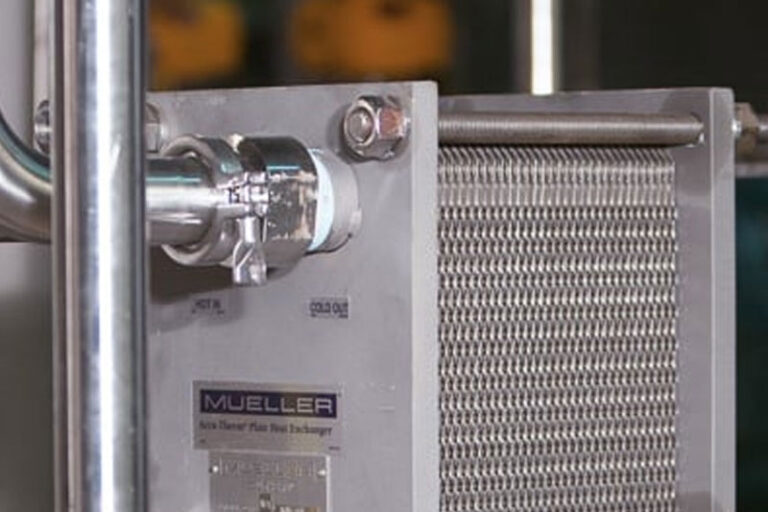

Plate Heat Exchanger

The Plate Heat Exchanger is one of the most common types of wort coolers. It consists of multiple metal plates with multiple channels between the plates for heat exchange between the wort and the cooling liquid. The advantage of the plate cooler is its efficient heat exchange ability, which can quickly reduce the temperature of the wort.

Tubular Cooler

A tubular Heat Exchanger is another common type of cooler, which conducts heat through a pipe system and the cooling liquid flows through another set of pipes, exchanging heat between the two sets of pipes. Compared with the plate cooler, the tubular cooler has a simple structure, but the cooling efficiency may be relatively low.

Snake Cooler

Immersion Chiller is a simple cooling device commonly used in beer brewing. It consists of a long metal pipe (usually copper or stainless steel pipe) through which cold water flows, and the pipe itself is immersed in hot wort. The cooling effect is relatively direct and suitable for small-scale brewing.

Air Cooled Heat Exchanger

Air Cooled Heat Exchanger directly exchanges heat with wort through the air, usually used in some occasions where energy saving is required, or when there is no cold water resource.

The role of wort cooler in brewing

Protect yeast activity

The most direct role of the wort cooler is to reduce the wort temperature to a range suitable for yeast fermentation. Yeast will be damaged or even die at higher temperatures, while at lower temperatures, yeast activity is low and the fermentation process is slow. The wort cooler can ensure that the wort is quickly cooled to a temperature suitable for yeast (usually between 18°C and 24°C), thereby ensuring that the yeast ferments in the best condition.

Reduce oxidation reaction

During the wort cooling process, if the cooling speed is too slow and the wort is exposed to the air for too long, oxygen may react with the components in the wort, causing oxidation of the beer, and affecting its taste and flavor. Rapid cooling can reduce the occurrence of oxidation reactions and keep the beer fresh and mellow.

Improve production efficiency

An efficient wort cooler can quickly reduce the temperature of the wort, thereby shortening the entire brewing cycle and improving production efficiency. In commercial brewing, time is cost. The use of efficient cooling equipment can complete the cooling process in a shorter time, ensuring the continuity and stability of production.

FAQ

What is a wort cooler?

A wort cooler is a device used to quickly cool the boiled wort. The purpose of cooling is to reduce the wort temperature to a range suitable for yeast fermentation, usually between 18°C and 24°C, so as to ensure the activity of the yeast and avoid the influence of oxidation on the flavor of the beer.

What role does a wort cooler play in the beer brewing process?

The main function of a wort cooler is to quickly cool the boiled wort so that yeast can be added for fermentation. If the wort is not cooled in time, the excessively high temperature may cause the yeast to lose its activity, affecting the fermentation process and, in turn, the quality of the beer. At the same time, rapid cooling can also reduce oxidation reactions and maintain the fresh taste and flavor of the beer.

Why is it necessary to cool the wort quickly?

The purpose of cooling the wort quickly is to prevent the yeast from being damaged by high temperatures and ensure that it can remain active during the fermentation process. At the same time, too slow a cooling speed may cause the oxygen in the wort to react with other components, producing an unpleasant oxidized taste and affecting the taste of the beer.

What can the cooling medium be?

A wort cooler usually uses cold water, ice water, or other refrigeration liquids as the cooling medium. The lower the temperature of the cooling medium, the faster the cooling rate is usually. Therefore, using a low-temperature cooling medium can improve the cooling efficiency and ensure that the wort cools down quickly.

Can a wort chiller be used in home brewing?

Yes, home brewers usually use a snake cooler or a small plate cooler to cool the wort quickly. The design of a home chiller is relatively simple and can provide enough cooling efficiency to ensure a smooth wort cooling process when brewing small batches.