After 15 years in the brewing industry and helping establish over 1000 commercial breweries, I’ve gained deep insights into what sets commercial brewing apart from homebrewing.

Commercial brewing is the large-scale production of beer for retail sale, using professional equipment and standardized processes to ensure consistent quality. It requires licensing, proper facilities, and adherence to food safety regulations.

Let me share my expertise about how commercial brewing operations work and what makes them successful.

Can You Make Money From Brewing?

Through years of consulting with brewery startups and established operations, I’ve developed clear insights into brewery profitability.

Yes, brewing can be profitable with typical profit margins ranging from 7% to 15% for well-managed operations. Success depends on factors like scale, market position, operational efficiency, and distribution strategy.

Understanding Brewery Profitability

The financial success of a brewing operation depends on multiple interconnected factors that must be carefully managed. From my experience helping hundreds of breweries optimize their operations, I’ve identified key elements that contribute to profitability.

Revenue Streams Analysis:

- Taproom sales (40-60% margins)

- Distribution sales (20-30% margins)

- Merchandise (50-70% margins)

- Events and tours (70-80% margins)

- Contract brewing (15-25% margins)

Operational Cost Management:

| Category | Percentage of Revenue | Control Measures |

|---|---|---|

| Raw Materials | 15-20% | Bulk purchasing, recipe optimization |

| Labor | 20-25% | Efficient scheduling, automation |

| Utilities | 8-12% | Energy-efficient equipment, recovery systems |

| Marketing | 5-10% | Social media, community engagement |

| Maintenance | 5-8% | Preventive maintenance programs |

Success Factors Include:

- Location strategy and market analysis

- Equipment selection and maintenance

- Quality control procedures

- Brand development

- Distribution partnerships

- Staff training programs

- Inventory management

- Waste reduction initiatives

Investment considerations must account for:

- Initial equipment costs

- Facility requirements

- Working capital needs

- Marketing budgets

- Emergency funds

What Is Commercial Fermentation?

Drawing from my extensive experience with fermentation systems, I can explain this crucial brewing process.

Commercial fermentation is the controlled conversion of sugars into alcohol using specific yeast strains in industrial-scale vessels. This process requires precise temperature control, pressure management, and monitoring systems.

Commercial Fermentation Process Analysis

Commercial fermentation represents a complex interplay of biological processes, engineering controls, and quality management systems. Based on my experience designing fermentation facilities, successful commercial fermentation requires careful attention to multiple factors.

Fermentation Control Parameters:

- Temperature regulation (±1°F precision)

- Pressure management (0-15 PSI)

- Dissolved oxygen levels

- pH monitoring

- Yeast cell counts

- Gravity measurements

Equipment Requirements:

| Component | Purpose | Specifications |

|---|---|---|

| Fermenters | Primary fermentation | Jacketed, pressure-rated |

| Glycol System | Temperature control | Calculated cooling capacity |

| CIP System | Sanitation | Automated cleaning cycles |

| Monitoring Systems | Process control | Real-time data logging |

Quality Control Procedures:

- Daily sampling protocols

- Laboratory analysis

- Flavor profiling

- Microbiological testing

- Documentation requirements

- Batch tracking systems

Process optimization strategies include:

- Yeast management programs

- Nutrient addition schedules

- Oxygen control systems

- Temperature profiling

- Pressure regulation

- Tank geometry considerations

What Is The Difference Between Craft Beer And Commercial Beer?

As someone who works with both craft and large commercial breweries, I understand the distinct characteristics of each approach.

Craft beer focuses on small-batch production, unique flavors, and traditional methods, while commercial beer emphasizes consistency, efficiency, and large-scale distribution. The main differences lie in production volume, ingredient selection, and brewing philosophy.

Analyzing Craft vs Commercial Brewing

The distinction between craft and commercial brewing encompasses multiple aspects of beer production, business operations, and market approach. Through my experience with both segments, I’ve observed significant differences in philosophy, process, and product.

Production Methodology Comparison:

- Batch sizes and frequency

- Automation levels

- Quality control approaches

- Innovation flexibility

- Equipment utilization

Operational Differences:

| Aspect | Craft Brewing | Commercial Brewing |

|---|---|---|

| Batch Size | 5-30 BBL | 100+ BBL |

| Recipe Variation | Frequent | Minimal |

| Ingredient Selection | Premium, varied | Standardized, bulk |

| Process Control | Manual/Semi-auto | Fully automated |

| Distribution | Local/Regional | National/Global |

Market Positioning Elements:

- Brand identity development

- Price point strategies

- Distribution channels

- Marketing approaches

- Consumer engagement

Quality Management:

- Testing protocols

- Consistency standards

- Shelf life requirements

- Package stability

- Flavor profiles

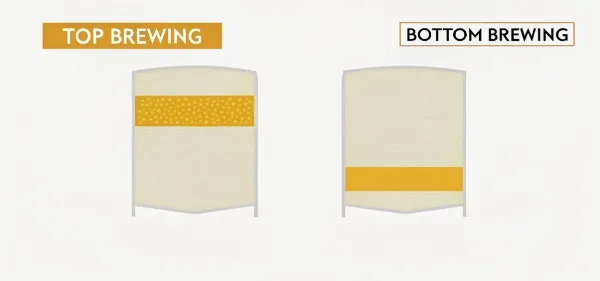

What Is Top Brewing Vs Bottom Brewing?

Having worked with various brewing methods throughout my career, I can explain these distinct fermentation approaches.

Top brewing uses yeast that ferments at warmer temperatures (60-75°F) and floats to the surface, while bottom brewing uses yeast that works at cooler temperatures (35-55°F) and settles to the bottom. Each method produces distinct beer characteristics.

Understanding Brewing Methods

The distinction between top and bottom brewing represents fundamental differences in yeast behavior, fermentation conditions, and resulting beer characteristics. My experience with both methods has provided deep insights into their technical requirements and practical applications.

Yeast Characteristics Analysis:

- Strain selection criteria

- Temperature tolerance

- Flocculation behavior

- Flavor production

- Alcohol tolerance

Process Requirements:

| Factor | Top Brewing | Bottom Brewing |

|---|---|---|

| Temperature | 60-75°F | 35-55°F |

| Duration | 3-7 days | 7-14 days |

| Pressure | Atmospheric | 0-15 PSI |

| Tank Design | Open/Closed | Pressurized |

| Cooling Needs | Moderate | Intensive |

Equipment Considerations:

- Fermentation vessel design

- Cooling system capacity

- Yeast handling equipment

- Transfer systems

- Monitoring instruments

Product Characteristics:

- Flavor development

- Clarity expectations

- Aging requirements

- Packaging conditions

- Shelf stability

Conclusion

Commercial brewing requires understanding multiple technical aspects, from equipment selection to process control. Success depends on balancing efficiency with quality while maintaining consistent production standards.