Hygiene and daily cleaning of brewery equipment is arguably the biggest challenge for brewers, but a good cleaning-in-place system (CIP System) can help. It may not be an exciting topic, but cleanliness is as essential to brewing quality craft beer like hops, water, and malt. It doesn’t matter whether you brew beer at home or

CIP systems are a must for the craft beverage industry to deliver quality products to a competitive market. The need to produce the highest quality products in the craft beverage sector is only going to get stronger. Using food-grade stainless steel to manufacture equipment is an important step in ensuring high-quality product hygiene and preventing

To maximize yields, the craft beer industry relies on a combination of clean-in-place (CIP) design, engineering, installation, control, monitoring, service, and repair expertise. Design and engineering expertise are especially valuable when upgrading CIP systems to improve water and chemical usage efficiency and optimize cleaning cycle duration and frequency. Therefore, it is important to understand the

For those unfamiliar with the word CIP, it’s a cleaning system. Beverage manufacturers (such as breweries) will utilize it to automatically clean and/or sanitize certain process equipment (such as pipes and tanks) without the need for disassembly. Many problems with these systems arise due to misinformation provided by “out of the box” CIP providers. These

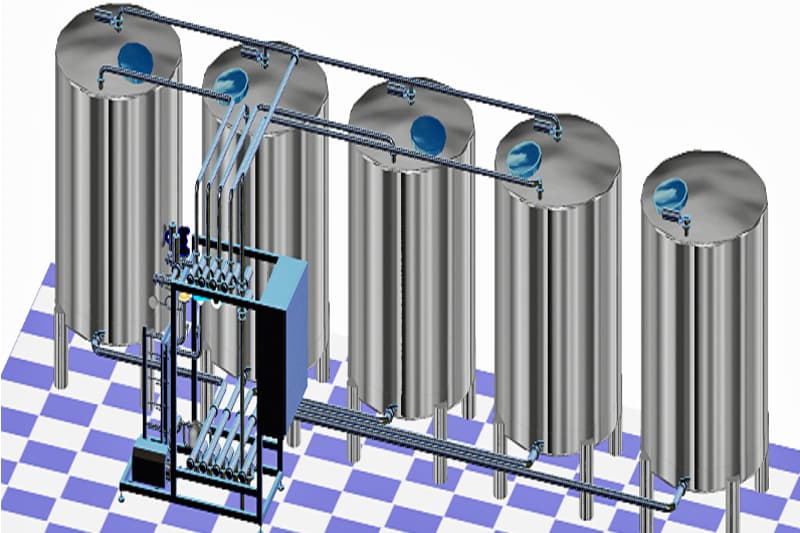

Maintaining a hygienic brewing environment to ensure beer quality is very important for any brewer. This is where a good clean-in-place (CIP) System comes in. A clean-in-place (CIP) is a combination of mechanical components and equipment for a solution that combines water, chemicals, and heat to clean brewery equipment. The chemical cleaning solution is pumped

A clean-in-place (CIP) system is a combination of mechanical components and equipment used to combine water, chemicals, and heat to create a cleaning solution. These chemical cleaning solutions are pumped or circulated by the CIP system through other systems or equipment and clean the brewery equipment. A good clean-in-place (CIP) system starts with great design

Hygiene and daily cleaning of brewery equipment is arguably the biggest challenge for brewers, but a good cleaning-in-place system (CIP System) can help. It may not be an exciting topic, but cleanliness is as essential to brewing quality craft beer like hops, water, and malt. It doesn’t matter whether you brew beer at home or

CIP systems are a must for the craft beverage industry to deliver quality products to a competitive market. The need to produce the highest quality products in the craft beverage sector is only going to get stronger. Using food-grade stainless steel to manufacture equipment is an important step in ensuring high-quality product hygiene and preventing

To maximize yields, the craft beer industry relies on a combination of clean-in-place (CIP) design, engineering, installation, control, monitoring, service, and repair expertise. Design and engineering expertise are especially valuable when upgrading CIP systems to improve water and chemical usage efficiency and optimize cleaning cycle duration and frequency. Therefore, it is important to understand the

For those unfamiliar with the word CIP, it’s a cleaning system. Beverage manufacturers (such as breweries) will utilize it to automatically clean and/or sanitize certain process equipment (such as pipes and tanks) without the need for disassembly. Many problems with these systems arise due to misinformation provided by “out of the box” CIP providers. These

Maintaining a hygienic brewing environment to ensure beer quality is very important for any brewer. This is where a good clean-in-place (CIP) System comes in. A clean-in-place (CIP) is a combination of mechanical components and equipment for a solution that combines water, chemicals, and heat to clean brewery equipment. The chemical cleaning solution is pumped

A clean-in-place (CIP) system is a combination of mechanical components and equipment used to combine water, chemicals, and heat to create a cleaning solution. These chemical cleaning solutions are pumped or circulated by the CIP system through other systems or equipment and clean the brewery equipment. A good clean-in-place (CIP) system starts with great design

Technical skills and training

Verify/Confirm

Temperature measurement

Pressure measurement

Flow measurement

Conductivity measurement

- Calibrate temperature probes, conductivity probes, and other sensors.

- Verify that the system is operating as expected, e.g. valves are opening/closing, cycle times are met, alarms are functioning properly, chemical concentrations and temperatures are met, etc.

- Open circuit after cleaning, perform visual observation and microbial/allergen monitoring of swab sites on specific equipment, and/or final rinse sample testing.

Documentation

Summarize

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive

Beer Brewery Equipment Manufacturer The brewing supplies provided by Micet Craft can support your brewing needs from small batches of micro beer brewing equipment to 100 barrels capacity. Micet Craft has reached cooperation with many breweries around the world, we can design and manufacture professional brewing systems for breweries, including cellar beer brewing equipment and other

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet Craft produced a variety of sizes and specifications of fermentation tanks. Customers can choose

Professional bright Beer tank manufacturer from China The bright tank is a vessel for storing and carbonated beer, it is also called the brite tank. The bright tank is an important part of the workflow of professional beer brewers. It can be used to store and carbonate beer, thus eliminating the trouble of cleaning beer

China brewing equipment manufacturer and suppliers Micet Craft has cooperated with breweries in many countries around the world to provide them with brewing equipment. We provide customers with turnkey brewery solutions, which include designing, manufacturing and installing customized breweries. The Micet Craft team has decades of experience in the manufacturing of brewing equipment, we not

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can provide a turnkey solution according to the daily output you need. We have brewhouse equipment with 2 vessels, 3 vessels and 4 vessels, the unique design allows you to do decoction

Professional beer filling machine manufacturer Beer filling machine is the core equipment of the beer production line. Our beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. Micet Craft provides you with a cheap and efficient way of filling beer. We

Best beer brewing system manufacturer from china Micet Craft is a professional beer brewing system manufacturer in China. We mainly produce high-end customized turnkey brewing systems. Whether you are planning to open a nano-brewery, microbrewery, or commercial brewery, we can provide you with the most complete turnkey solution. Our beer brewing systems are all price-competitive